Corporate Social Responsibility (CSR) is a must for any toy brand that wants to achieve growth and avoid the costly implications of non compliance. A company that is testament to this fact is Lego. Last year the toy giant reported its highest revenue yet in its 85 year history, their profits rising 1.7% to 12.2bn kroner. This growth showcases the heights you can achieve through organizational commitment.

Global retail brands are increasingly wanting to partner with suppliers of children’s toys who can provide them with the appropriate environmental and social compliance.

Lego has been able to achieve their CSR goals through going above and beyond what any toy quality management system requires.

How have they done this?

Renewable energy.

In 2012 the toy company began investing in wind turbines to power their operations globally. As a result, in 2016 more than 360 gigawatt hours of energy was used by the LEGO Group to produce the more than 75 billion LEGO bricks sold around the world during the year.  They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

How can your QMS leverage CSR for a globally competitive position?

Let’s take a bit of a deeper dive in… A QMS framework is just that: A framework that has been created to ensure quality in all areas from management to products, to customers, to factory processes and environmental impact. The ISO 14001:15 is the international standard used to navigate environmental impact and innovations. What are the key benefits of complying with ISO 14001:15?- It demonstrates compliance with current regulatory requirements.

- It increases leadership involvement and engagement of employees.

- It improves company reputation and the confidence of stakeholders through strategic communication.

- It achieves strategic business aims by incorporating environmental issues into its business management.

- It provides a competitive and financial advantage through improved efficiencies and reduced costs.

- It encourages better environmental performance of suppliers by integrating them into the organization’s business systems.

How can your toy brand go about implementing ISO today?

We have outlined a stepped process which will help you prepare for compliance according to the environmental ISO 14001 framework for your brand;- You will need to identify all aspects and environmental impacts of your organization’s activities

- If you have not established an environmental policy for your organization, you will need to go ahead and do this.

- You will need to formalize your environmental procedures and publish them in company manuals and company policy.

- You will need to bring the company into compliance with all legal requirements and mandatory regulations.

- You will need to get the confirmation of compliance by all stakeholders such as clients and legal authorities.

- Lastly, you will need to obtain a certification of your environmental management system by a registered third party.

.png)

It is at this point that

It is at this point that A random furniture sample will be selected at this point, where they will each be checked one by one to inspect whether or not they meet the following;

A random furniture sample will be selected at this point, where they will each be checked one by one to inspect whether or not they meet the following;

A social compliance audit can be difficult to attain, but is an absolute necessity for that transparent supply chain your consumers today are demanding.

A social compliance audit ensures that a factory and its practices are abiding by all local laws and that you meet all of the social obligations as set out by the guidelines of the audit, from fair wages to no instances of child labor in a factory.

In this blog post, I will outline the exact procedure of this audit, the benefits it offers to your consumer electronics brand and how you can go about conducting this audit for yourself.

So, let’s dive in…

A social compliance audit can be difficult to attain, but is an absolute necessity for that transparent supply chain your consumers today are demanding.

A social compliance audit ensures that a factory and its practices are abiding by all local laws and that you meet all of the social obligations as set out by the guidelines of the audit, from fair wages to no instances of child labor in a factory.

In this blog post, I will outline the exact procedure of this audit, the benefits it offers to your consumer electronics brand and how you can go about conducting this audit for yourself.

So, let’s dive in…

Document reviews – Auditors will check all the documentation of the supplier to determine the presence of any possible child labour, an all too common violation within the consumer electronics industry. They also assess whether there are any violations of extended working hours and wages. They will also look into what types of social insurance are available to workers and review any fire and safety documentation, which will help to determine whether or not any safety precautions or plans are in place. They will also inspect whether or not there is any environmental monitoring being done and, if so, how it is conducted.

Employee interviews – The auditors conduct interviews with the factory in question staff, where they ask them about their working hours, overtime, and about their holiday/leave time. Auditors also like to cross check these statements by interviewing factory management to ensure there are no discrepancies. This helps to clarify whether there are any instances of abuse or misconduct between staff and management. In the case of a re-audit these interviews will then be conducted again to ensure improvement plans are being implemented properly.

Closing meeting with audit status – This meeting reveals the audit results of your CE factory and also makes suggestion for improvements. If you use

Document reviews – Auditors will check all the documentation of the supplier to determine the presence of any possible child labour, an all too common violation within the consumer electronics industry. They also assess whether there are any violations of extended working hours and wages. They will also look into what types of social insurance are available to workers and review any fire and safety documentation, which will help to determine whether or not any safety precautions or plans are in place. They will also inspect whether or not there is any environmental monitoring being done and, if so, how it is conducted.

Employee interviews – The auditors conduct interviews with the factory in question staff, where they ask them about their working hours, overtime, and about their holiday/leave time. Auditors also like to cross check these statements by interviewing factory management to ensure there are no discrepancies. This helps to clarify whether there are any instances of abuse or misconduct between staff and management. In the case of a re-audit these interviews will then be conducted again to ensure improvement plans are being implemented properly.

Closing meeting with audit status – This meeting reveals the audit results of your CE factory and also makes suggestion for improvements. If you use  In understanding the ethical compliance standards as laid out above, you are able to make informed decisions about the suppliers you choose to use in the manufacturing of your electrical products.

In understanding the ethical compliance standards as laid out above, you are able to make informed decisions about the suppliers you choose to use in the manufacturing of your electrical products.

On 23rd December 2014, the Consumer Product Safety Commission (CPSC) announced the recall of over 7 million coffee machines.Between 2010-2014, there were over 200 complaints of boiling water spraying out of the machine and approximately 90 burn injuries reported.It has been recently announced that Keurig has

On 23rd December 2014, the Consumer Product Safety Commission (CPSC) announced the recall of over 7 million coffee machines.Between 2010-2014, there were over 200 complaints of boiling water spraying out of the machine and approximately 90 burn injuries reported.It has been recently announced that Keurig has  In fact, the inventor today does not get a dime out of the sales of this popular children’s toy, as she was told her idea was not good enough and wouldn’t sell. Needless to say, millions of these toys are sold the world over.

But, she could count that as somewhat of a blessing…

Recently, over

In fact, the inventor today does not get a dime out of the sales of this popular children’s toy, as she was told her idea was not good enough and wouldn’t sell. Needless to say, millions of these toys are sold the world over.

But, she could count that as somewhat of a blessing…

Recently, over  It turns out that

It turns out that  Many organizations do not have the extensive geographical networks that larger retailers have.

Therefore your internal staff ends up spending a lot of time traveling for quality control inspections, with not enough time spent focusing on the quality of a product. This often slows down production processes, with a longer eventual time to market.

If we take the Fidget Spinner example into consideration, what is the likelihood of your in-house team being aware of that noncompliance before it hit the market.

Think about it.

An occurrence such as the above puts your brand at an unnecessary risk, with the potential for bad publicity and a major loss in sales.

Can your organization afford this?

Many organizations do not have the extensive geographical networks that larger retailers have.

Therefore your internal staff ends up spending a lot of time traveling for quality control inspections, with not enough time spent focusing on the quality of a product. This often slows down production processes, with a longer eventual time to market.

If we take the Fidget Spinner example into consideration, what is the likelihood of your in-house team being aware of that noncompliance before it hit the market.

Think about it.

An occurrence such as the above puts your brand at an unnecessary risk, with the potential for bad publicity and a major loss in sales.

Can your organization afford this?

Some testing equipment may be unique to a specific product or if there is an update in testing procedures to be inclusive of recent changes in regulation.

Often external providers are able to provide technical solutions based on the above specifications, along with teams that are well versed in new testing procedures.

External providers will often send their inspectors on training to familiarize themselves with new equipment and testing procedures to ensure a high quality service is offered with a minimum product recall rate.

For third party quality providers it is a priority to be up to date with the latest trends and developments in your industry along with the best practices that you should be following.

This kind of knowledge and expertise can be leveraged to your competitive advantage.

Some testing equipment may be unique to a specific product or if there is an update in testing procedures to be inclusive of recent changes in regulation.

Often external providers are able to provide technical solutions based on the above specifications, along with teams that are well versed in new testing procedures.

External providers will often send their inspectors on training to familiarize themselves with new equipment and testing procedures to ensure a high quality service is offered with a minimum product recall rate.

For third party quality providers it is a priority to be up to date with the latest trends and developments in your industry along with the best practices that you should be following.

This kind of knowledge and expertise can be leveraged to your competitive advantage.

your product.

Add all of this together, and you begin to see higher profit margins and the ability in which you can meet your products supply and demand will also have grown, creating that desired competitive advantage.

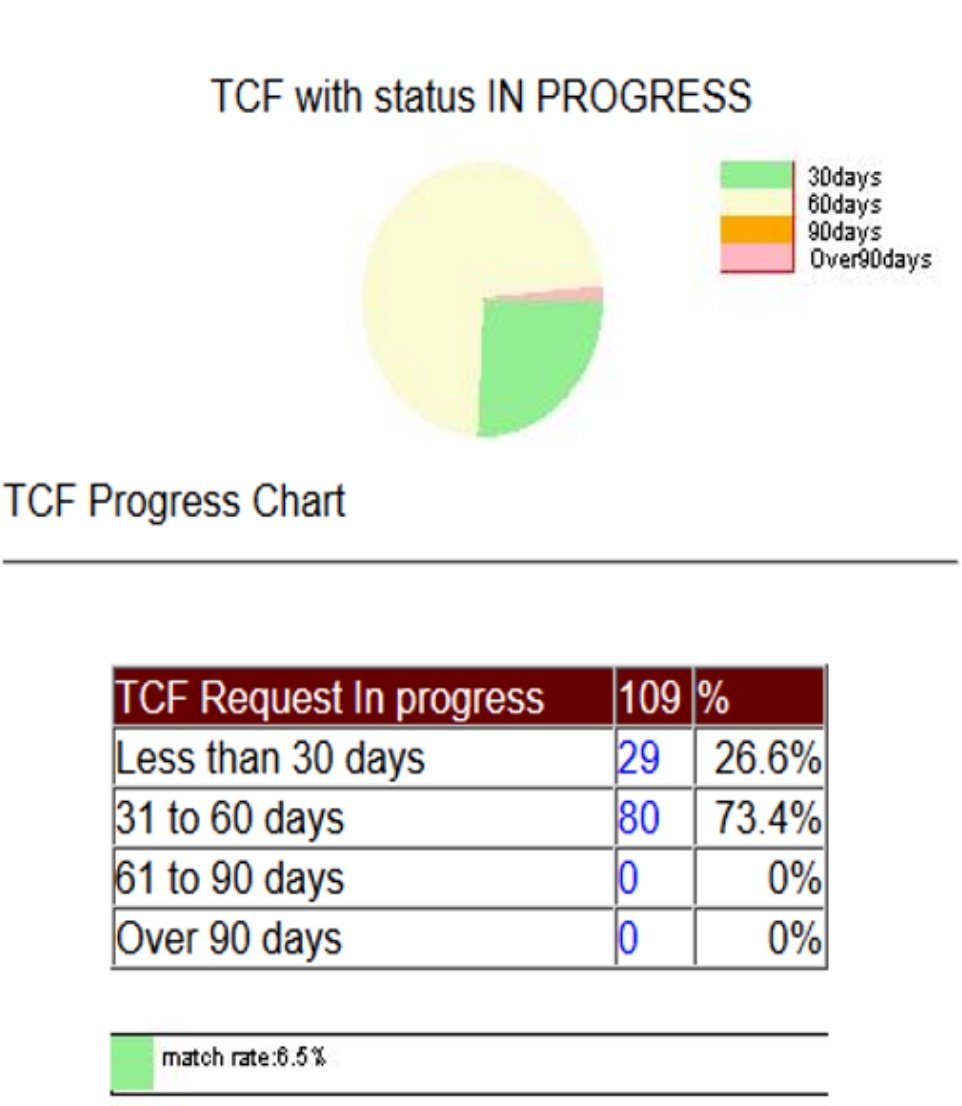

Let’s take a brief look at the Technical Compliance File solution;

This is a compliance solution that allows you reliable and accurate insights into your compliance processes.

It is offered through a web-based platform and is a

your product.

Add all of this together, and you begin to see higher profit margins and the ability in which you can meet your products supply and demand will also have grown, creating that desired competitive advantage.

Let’s take a brief look at the Technical Compliance File solution;

This is a compliance solution that allows you reliable and accurate insights into your compliance processes.

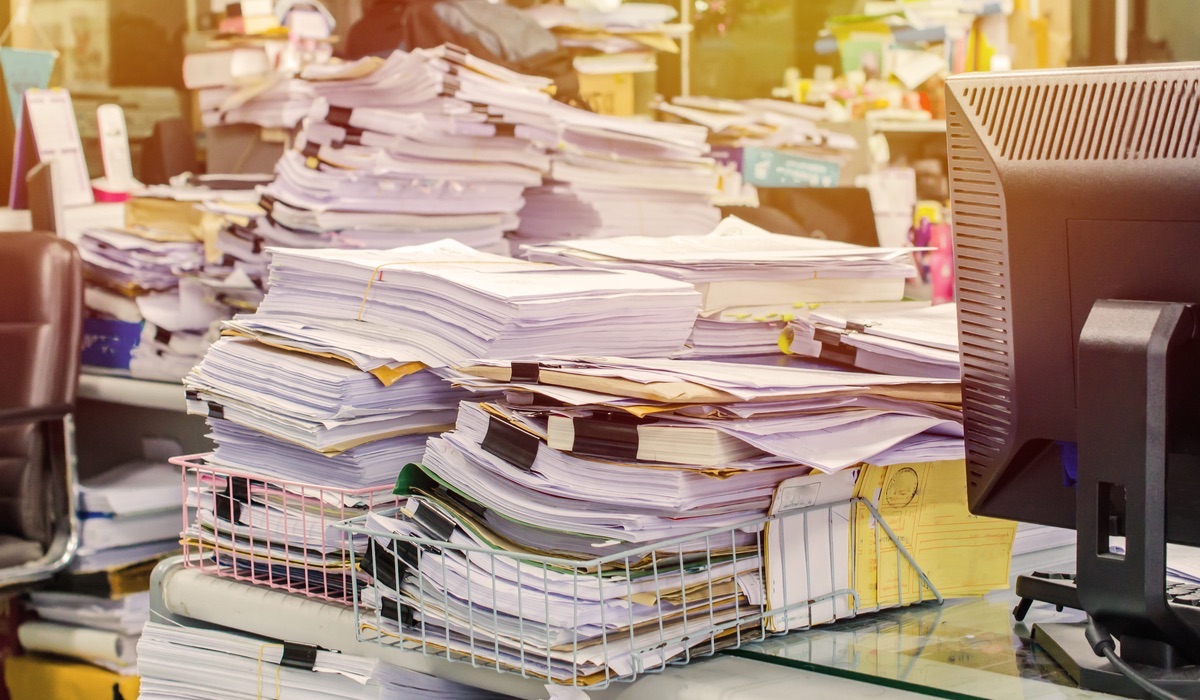

It is offered through a web-based platform and is a  Inspection reports are essential in getting shipments released from customs. It will be up to the retailer alongside your quality provider to set up a report rating guideline.

This report rating guideline forms a baseline of automation which reduces the amount of manual changes after the reports review. The manual reviewing of these reports slow down the auto shipment processes immensely and this entire process becomes less meaningful.

An external quality provider will be able to provide you with industry knowledge and best practices relating to rating reports. You will also be able customize your rating reports according to your product needs.

Once this report rating has been created, your quality provider can utilize their technical systems to send daily reports to both the client and your chosen cargo company. This creates a much clearer and faster release process for both you and the cargo company.

The mountain of paperwork from import licenses to full inspection reports, they have it down to a tee, enabling a streamlined, efficient process for your organization.

Inspection reports are essential in getting shipments released from customs. It will be up to the retailer alongside your quality provider to set up a report rating guideline.

This report rating guideline forms a baseline of automation which reduces the amount of manual changes after the reports review. The manual reviewing of these reports slow down the auto shipment processes immensely and this entire process becomes less meaningful.

An external quality provider will be able to provide you with industry knowledge and best practices relating to rating reports. You will also be able customize your rating reports according to your product needs.

Once this report rating has been created, your quality provider can utilize their technical systems to send daily reports to both the client and your chosen cargo company. This creates a much clearer and faster release process for both you and the cargo company.

The mountain of paperwork from import licenses to full inspection reports, they have it down to a tee, enabling a streamlined, efficient process for your organization.

Traditionally an inhouse team often releases inspection reports as and when they receive them causing major delays, this is often due to in-house QC teams needing to travel extensively, which means they don’t have enough time to make the approvals that are needed for the shipments to be released in a timely manner.

Not to sound repetitive, but to have an in-house team that has the capacity to manage the logistics involved with shipping would be a dream, no doubt, but getting through customs safely stems from being efficient in all the other points I’ve made above.

In-house teams without the right amount of time, resources and technical expertise will struggle to cope with issues that could have otherwise been prevented.

So here’s the deal…

Managing quality is a complex system that needs 100% of your attention and focus.

Are you able to dedicate that kind of time and resource to ensuring just that?

This is a question that many often do not want to answer, but the reality is that you often cannot afford the time and resource that goes into creating fully optimized quality systems that can produce high-quality products for your brand and on time.

So, what then?

It might be worth considering hiring an external third party quality provider that can give you the time and resources that you need to streamline your supply chain operations.

A third party quality provider is able to provide you with;

* The latest in product regulation

* Technical expertise

* They have the appropriate technology to streamline your operations

* They have the know how on how to navigate the waters of international logistics for your brand.

This will give you room to begin focusing on what you are good at; producing those high-quality products and creating a level of trust with your consumer that is globally competitive.

Have experienced working with third party quality inspection services?

Traditionally an inhouse team often releases inspection reports as and when they receive them causing major delays, this is often due to in-house QC teams needing to travel extensively, which means they don’t have enough time to make the approvals that are needed for the shipments to be released in a timely manner.

Not to sound repetitive, but to have an in-house team that has the capacity to manage the logistics involved with shipping would be a dream, no doubt, but getting through customs safely stems from being efficient in all the other points I’ve made above.

In-house teams without the right amount of time, resources and technical expertise will struggle to cope with issues that could have otherwise been prevented.

So here’s the deal…

Managing quality is a complex system that needs 100% of your attention and focus.

Are you able to dedicate that kind of time and resource to ensuring just that?

This is a question that many often do not want to answer, but the reality is that you often cannot afford the time and resource that goes into creating fully optimized quality systems that can produce high-quality products for your brand and on time.

So, what then?

It might be worth considering hiring an external third party quality provider that can give you the time and resources that you need to streamline your supply chain operations.

A third party quality provider is able to provide you with;

* The latest in product regulation

* Technical expertise

* They have the appropriate technology to streamline your operations

* They have the know how on how to navigate the waters of international logistics for your brand.

This will give you room to begin focusing on what you are good at; producing those high-quality products and creating a level of trust with your consumer that is globally competitive.

Have experienced working with third party quality inspection services?  Product specification can look anything like your products dimensions, the volume, it’s weight, the color and any specific labeling that it may need to meet regulation.

In your specifications you need to ensure that you are as specific as you can possibly be, from specific color palettes to the maximum weight of an electric blender. The more specific you are, the easier it will be for your supplier to meet your specifications.

These specifications will also provide your supplier’s quality control team with a standard/guide to monitor the production of the item appropriately.

This is where the

Product specification can look anything like your products dimensions, the volume, it’s weight, the color and any specific labeling that it may need to meet regulation.

In your specifications you need to ensure that you are as specific as you can possibly be, from specific color palettes to the maximum weight of an electric blender. The more specific you are, the easier it will be for your supplier to meet your specifications.

These specifications will also provide your supplier’s quality control team with a standard/guide to monitor the production of the item appropriately.

This is where the

A laptop’s battery overheating that when unattended whilst charging can cause fires would be classified as a critical defect.

A laptop’s battery overheating that when unattended whilst charging can cause fires would be classified as a critical defect.

Therefore an important question you should be asking your supplier before all this is, how they will go about preventing any quality issues that may arise during your operation?

Understanding how your supplier handles quality pressures and compliance procedures will help define what kind of relationship you have with them.

Before mass production, your supplier needs to provide you with a

Therefore an important question you should be asking your supplier before all this is, how they will go about preventing any quality issues that may arise during your operation?

Understanding how your supplier handles quality pressures and compliance procedures will help define what kind of relationship you have with them.

Before mass production, your supplier needs to provide you with a .jpg)

is also a dedicated IT team to ensuring the safety of the software and only API employees are allowed to make modifications to the platform.

is also a dedicated IT team to ensuring the safety of the software and only API employees are allowed to make modifications to the platform. Many of the compliance complexities that arise are in the collection and gathering of all the necessary documentation. Many manufacturers, importers and retailers today are still operating on outdated systems like spreadsheets, creating unreliable data and documentation, which creates an almost insurmountable task trying to maintain the information for each product reference.

Many of the compliance complexities that arise are in the collection and gathering of all the necessary documentation. Many manufacturers, importers and retailers today are still operating on outdated systems like spreadsheets, creating unreliable data and documentation, which creates an almost insurmountable task trying to maintain the information for each product reference.  you insight into your compliance status whenever you need it. There are also progress charts allowing you actionable insight into timelines and your supplier progress. This solution is also able to store all your documents for up to 10 years, ensuring your documents are safely stored for any future reference.

you insight into your compliance status whenever you need it. There are also progress charts allowing you actionable insight into timelines and your supplier progress. This solution is also able to store all your documents for up to 10 years, ensuring your documents are safely stored for any future reference.