The international supply chain is presently grappling with regular disruptions and uncertainties due to a variety of factors such as shifts in the geopolitical environment, disruptions in key global trade routes, and policies related to climate change. These issues present substantial risks and strains on companies, necessitating them to enhance their supply chain visibility, traceability, and transparency to effectively tackle these challenges.

A crucial element of ethical sourcing is supply chain mapping. Ethical sourcing requires companies to consciously and actively source and procure goods and services in a manner that is ethical, sustainable, and socially responsible. This implies that a firm will ensure that its business operations, both internally and throughout its supply chain, do not negatively impact people and the environment.

The initial stage in supply chain due diligence and traceability is Supply Chain Mapping. This is crucial when providing compliance reports regarding regulations on forced labour, the German Supply Chain Act, the Corporate Sustainability Due Diligence Directive, EUDR (European Union Regulation on Deforestation-free products), the California Transparency in Supply Chain Act, the UK Modern Slavery Act, among other regulations.

Understanding Supply Chain Mapping

Supply chain mapping is the process of creating a full picture of the network of activities and entities involved in producing and delivering a product.

Supply chains can be extremely complex, often involving multiple tiers with numerous suppliers in each tier. While most companies know who their Tier 1 suppliers (main manufacturers) are, the visibility often ends there. Taking the example of a wooden chair, the supply chain starts with harvesting trees from forests, then continues with timber processing, transporting and distributing, and ends with manufacturing and delivering the finished goods to end-users and consumers.

It is important to map the entire supply chain to gain a thorough understanding of the business and the entities it works with. This process involves more than just recognizing the top tiers; it necessitates comprehending the flow of materials and products within the chain, the relationships among various stakeholders, and the external factors that affect these interactions.

Why is supply chain mapping important for businesses?

The benefits of Supply Chain Mapping:

- To manage risks

Supply chain mapping is an essential tool for businesses to identify potential risks and opportunities for improvement within their supply chain. By pinpointing risks and areas for improvement, companies can take measures to mitigate risks, such as diversifying their supplier base and improving the resilience of their supply chains. - To Improve efficiency and reduce costs

With a better understanding of the supply chain, businesses can take measures to streamline processes, minimise waste, and enhance communication and coordination with suppliers and customers. - To ensure regulatory compliance

In addition, understanding your multi-tier supply chain is critical for compliance with regulations on supply chain due diligence and to meet ESG reporting requirements. - To become more transparent and sustainable

Today’s consumers are more conscious about product origin, sustainability, and safety. According to a McKinsey survey, 66% of all respondents and 75% of millennials consider sustainability when making a luxury purchase. An environmentally sustainable supply chain can help improve a brand’s reputation and market position.

Challenges with Supply Chain Mapping

In today’s globalized sourcing environment, companies, regardless of their size, have suppliers located in various parts of the world. As a result, organizations must oversee supply chains that cross boundaries and continents. This presents numerous difficulties stemming from communication, logistics, cultural distinctions, language obstacles, and regulatory compliance.

Businesses encounter multiple challenges in supply chain visibility. These include intricate supply chain networks, absence of standardized systems and clarity, inadequate understanding of supply chain mapping, reluctance in information sharing, and unauthorized subcontracting and raw material sourcing.

API can help you map your supply chain

Mapping your supply chain is not an easy task. API’s household goods and toy experts can assist your company in the identification and end-to-end mapping of all suppliers. We have experience mapping supply chains for companies around the world.

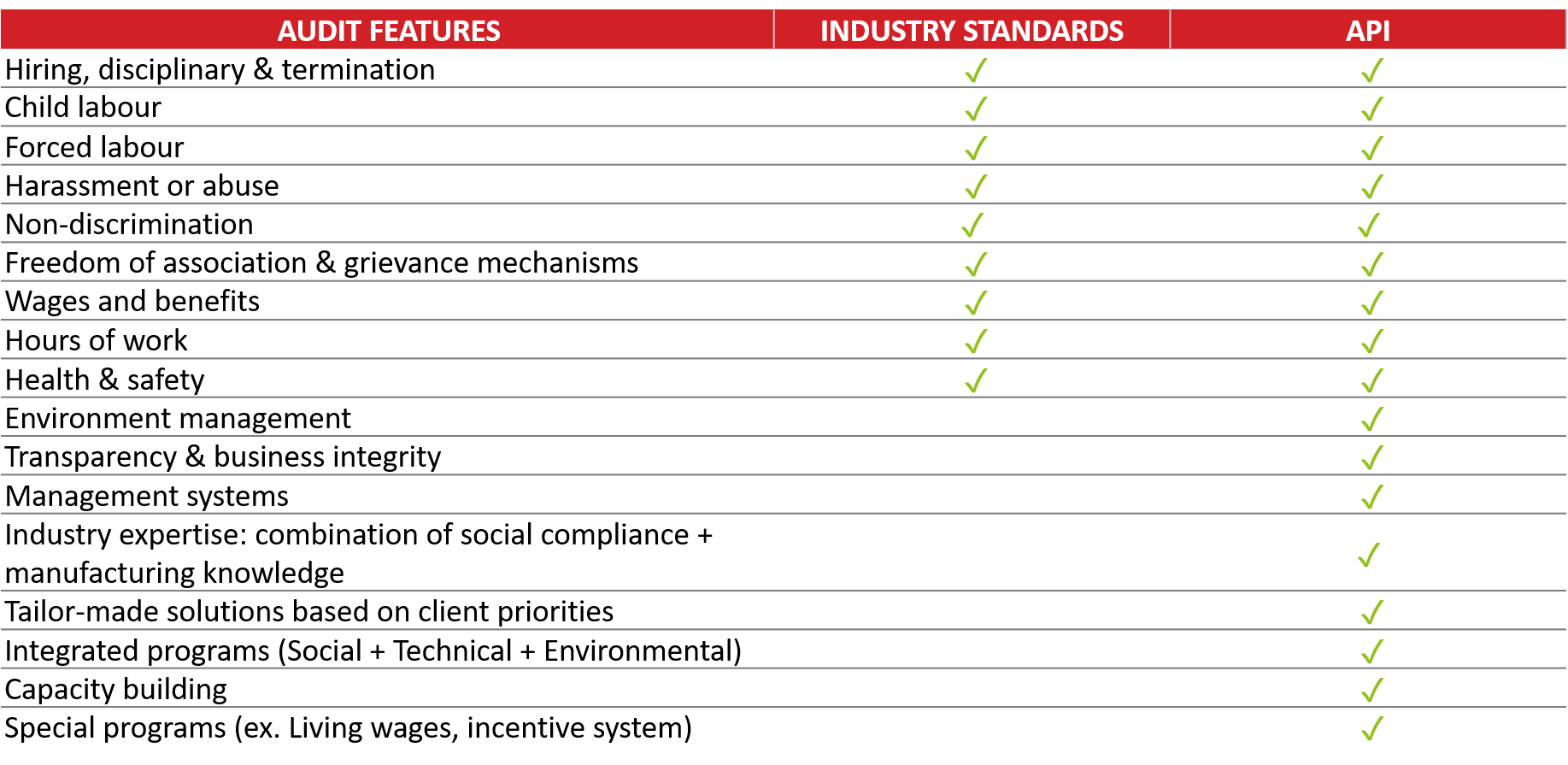

API’s added value:

- Cross expertise: CSR + Sustainability + Technical departments working closely together. Combining knowledge and expertise.

- Field Experience: Thanks to our teams being on the ground at the factories in real time, API’s household goods specialists are uniquely positioned to understand the manufacturing process and its challenges. This allows us to provide bespoke services to address issues at each and every one of the manufacturing stages to help our customers achieve their sustainability goals.

- Sustainability training / seminars: We offer sustainability training for your internal teams, suppliers and factories in English or in your local language.

API creates programs that are tailored to meet the specific requirements of each customer. To find out more about supply chain mapping services, Contact Us.