Product recalls are a veritable nightmare!

There is no other way to express the dread and that sinking feeling when the customer complaints start rolling in, and you begin considering whether or not to announce a recall.

A recall will spell significant damage to your brand image, and thousands, if not millions of loss in revenue.

Yes, you may argue that retailers are insured against recalls, but building trust with your customers is a difficult task at the best of times.

The digital age has also made it more difficult to hide the smallest of quality problems from your customers, and rebuilding trust from slip-ups that could have been prevented just adds fuel to a fire that won’t stop burning.

But it’s not all doom and gloom…

Product recalls can be prevented through best practice QC procedures, through due diligence, through strategic planning and implementation, through proper inspection reports and appropriate product testing to ensure that your compliance issues are a thing of the past.

In this blog post, we take a look at four product recalls from household goods and electronic giants in recent history, that could have been prevented through a bit of due diligence, through proper testing procedures and reliable quality management service providers.

1. Keurig Coffee Makers To Pay $5.8 Million In Civil Penalties

Keurig is a well-known coffee machine brand in the United States, with many corporate offices around the country being dotted with these machines, where it fast became an office staple.

But, imagine this.

Waking up to make that quick cup of coffee before work, or even offering an important investor a cup of coffee before heading into a meeting, and your machine begins to steam and spit out boiling water, causing a potential burn injury.

Not an ideal situation…

This left Keurig in some seriously ‘hot water’!

On 23rd December 2014, the Consumer Product Safety Commission (CPSC) announced the recall of over 7 million coffee machines.Between 2010-2014, there were over 200 complaints of boiling water spraying out of the machine and approximately 90 burn injuries reported.It has been recently announced that Keurig has

agreed to pay over $5.8 million in civil penalties to the government.

This penalty is to settle the charges against Keurig as they knew about the product’s defect, but failed to report it and continued to export the product despite the fact that it can and did cause major injuries.

What should have been done differently?

Keurig appealed to consumers to request a repair kit that was able to fit onto the product free of charge.

In reviewing the repair kit installation guidelines, it consisted of a new basket with a rubber seal to ensure that no hot water or steam would escape during use causing potential for burn injuries.

There was also an extra handle that slides over the original one to avoid direct contact with the hot water or steam that may be released when the handle is in position, or if hot water or steam is released during use, it would be pushed in the downward or upward position.

This kind of repair kit tells us that problem was related to product design more than any manufacturing or quality control issues.

This story also tells us how that at times it may not be enough to be in compliance with just the testing regulation.

There may be times when specific tests need to be developed to beyond the standard testing criteria, simulation tests are often a good example here; where a quality control team can simulate the kind of tough operating environment that a specific product may need.

This can often be done through a thorough risk assessment that should be completed during the product design stage.

The CPSC has not been able to disclose any more information as to what caused the defects, but that Keurig has agreed to

build and implement a compliance program to ensure that they comply with the Consumer Product Safety Act.

Adopting a compliance program stands as the rules, standards, regulations and requirements your organization sets for its suppliers, as this will grant you full transparency into supply chain operations.

A compliance program should not just be another program that importers tick off on an annual basis. It should become a key outcome and a reflection of an effective and efficient organization.

The key to a successful compliance program will be how well you can integrate compliance procedures into every facet of your brand.

2. Hasbro Recalls 1 Million Easy Bake Ovens

You have found that perfect Christmas gift for your little ones.

One that will create all those cute little memories that you will hold onto for a lifetime.

Then, a cry for help as their hand is stuck inside the toy under the element, causing some serious injury.

Quite far from a ‘Merry’ Christmas…

Hasbro was in deep with

over 1 million easy bake ovens that were recalled and over 77 reports of injury, and a report of one five year old being burnt so terribly that a partial finger amputation was needed.

What should have been done differently?

There was a finger entrapment test that was developed under the ASTM F963 as an industrial standard, but which only came into regulation in 2013 under the

Consumer Product Safety Improvement Act (CPSIA).

Currently, all

toys and children’s products need to be designed to comply with this ASTM F963 standard.

Retailers should be requesting that their manufacturers and suppliers need to be testing in compliance with this regulation, and have to be passed through an accredited third party lab before mass production can begin.

In meeting this criteria, there will also have to be a double check; either during inspection or through the lab with a random sample that is picked during the inspection process.

Procedures like this help to minimize potential risk and recall of a noncompliant product.

3. Sony To Pay $19 Million Dollars in Battery Recall

Exploding Dell notebooks with non-compliant Sony batteries.

A match made in retail hell.

4.1 million batteries in Dell notebooks needed to be recalled for overheating and potentially catching fire.

Research says that this was due to metallic particles being present in the critical parts of the batteries, at certain times causing instability in the battery.

These batteries were not only used in Dell computers, but other brands like Apple as well, so they recalled over 10 million batteries in total.

Sony has recently

agreed to pay $19 million dollars as settlements to this ongoing lawsuit.

What could have been done differently?

It has been said that the reason for this potential hazard was due to the presence of metallic particles, in the battery, in particular; nickel was found in these batteries. It unexpectedly got into the battery during the manufacturing process during two stages of the production process.

Here we can assess that the factory’s quality systems should have been reviewed and as to whether or not their QC team followed best practice in identifying potential defects.

There may have been bad storage practices causing a mix up between defective products and good one’s.

A root-cause analysis would have been needed to adjust the production line to fix the problem. Once this analysis is completed and amendments made by the retailer, a third party representative would need to validate the preventative and corrective action for the defect.

Factory audits can be an essential to safeguarding against product defects and recalls.

Practice due diligence here, ensure your quality control team is on top form and up to date with the latest in testing and regulation.

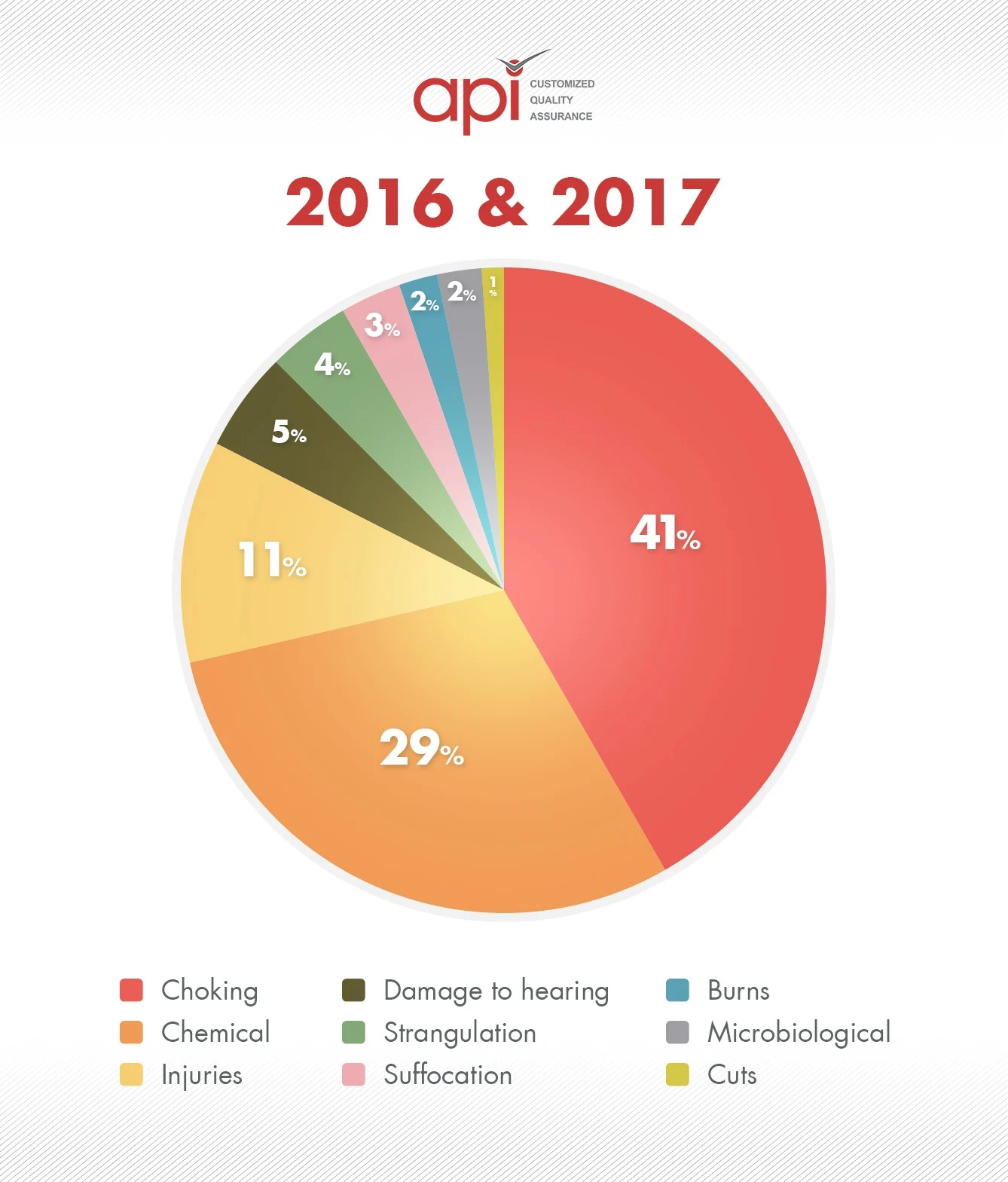

4. Fidget Spinners – Over 200 000 Have Been Recalled!

The latest craze amongst children all over the world.

The invention was originally intended to improve fine motor skills in children with learning disabilities, but grew in its popularity faster than what one could even blink.

In fact, the inventor today does not get a dime out of the sales of this popular children’s toy, as she was told her idea was not good enough and wouldn’t sell. Needless to say, millions of these toys are sold the world over.

But, she could count that as somewhat of a blessing…

Recently, over

200, 000 of them had to be recalled as they caused major harm to many children, with fingers getting stuck in the outer bearings to smaller parts being swallowed, where surgery was needed.

What could have been done differently?

This toy is specific in the types of international regulation and compliance that it needs to meet, but not many retailers can provide the necessary compliance documentation for this product.

It has been urged to rather seek out the compliant toys with all the necessary risk and warning labels on them.

As per international standard for general toys, it is required to drop this toy a few times only. This dropping of the toy often does not take into consideration just how often children drop these spinners. These spinners are dropped multiple times a day by end users, so this test in fact may not represent an adequate simulation.

A factory should be creating tough testing procedures to simulate the type of environment this toy will likely be exposed to.

These tests need to go beyond the standard testing criteria to ensure a durable, safe spinner is found in your children’s hands.

Apart from the strict QC procedures that should have been conducted, the correct lab tests should have been followed, as some spinners (the ones with batteries) were found to have high levels of lead present, posing a threat to its end consumers.

The appropriate chemical tests should have been performed to identify these chemical risks early on, giving your supplier time to rework the product to meet its compliance standards.

Conclusion

Strict quality control procedures need to be followed.

By ensuring you follow QC best practices for your product you begin to safeguard your brand, your product and even your end-consumer from a potentially bad quality product that can injure them, and cost you millions in revenue.

If you are not using a third party quality provider for all your testing and compliance procedures conducting things like; pre-purchase testing and inline inspections can be key to identifying these defects early on.

A bit of due diligence and strict QC procedures can go a long way in saving you the terrifying reality of product recalls and persistant compliance issues.

There are More Lessons To Be Learnt In This Case Study!

Are you ready to begin optimizing your processes?

Effectively managing growing supply chain complexities is something that most purchasing managers/importers deal with on a day to day basis.

As your brand grows compliance issues you never knew were there (nor were prepared for) may rear their ugly head, and it’s up to you to begin pinpointing issues and plugging the holes your profits will fall through, before the consumers of today tear them open even wider.

Ensuring product compliance starts and ends with one thing:

A robust compliance program.

Effectively managing growing supply chain complexities is something that most purchasing managers/importers deal with on a day to day basis.

As your brand grows compliance issues you never knew were there (nor were prepared for) may rear their ugly head, and it’s up to you to begin pinpointing issues and plugging the holes your profits will fall through, before the consumers of today tear them open even wider.

Ensuring product compliance starts and ends with one thing:

A robust compliance program.

Effectively managing growing supply chain complexities is something that most purchasing managers/importers deal with on a day to day basis.

As your brand grows compliance issues you never knew were there (nor were prepared for) may rear their ugly head, and it’s up to you to begin pinpointing issues and plugging the holes your profits will fall through, before the consumers of today tear them open even wider.

Ensuring product compliance starts and ends with one thing:

A robust compliance program.

Effectively managing growing supply chain complexities is something that most purchasing managers/importers deal with on a day to day basis.

As your brand grows compliance issues you never knew were there (nor were prepared for) may rear their ugly head, and it’s up to you to begin pinpointing issues and plugging the holes your profits will fall through, before the consumers of today tear them open even wider.

Ensuring product compliance starts and ends with one thing:

A robust compliance program.

Let’s take a look at what Walmart did; They created what they call the Sustainability Index, which is essentially a scorecard for suppliers to be reported on from various social and environmental production factors.

Walmart has said that by the end of 2017 that 70% of its products will come from suppliers who participate through this Index, and as a benefits they will be endorsed as a sustainable partner and proud Walmart supplier.

Solutions

Supply chain compliance is an important issue to address, with many local retail brands realising that compliance needs to be a top priority to be achieved in order to achieve a globally competitive advantage in the market.

So how do we go about achieving just that?

Let’s take a look at what Walmart did; They created what they call the Sustainability Index, which is essentially a scorecard for suppliers to be reported on from various social and environmental production factors.

Walmart has said that by the end of 2017 that 70% of its products will come from suppliers who participate through this Index, and as a benefits they will be endorsed as a sustainable partner and proud Walmart supplier.

Solutions

Supply chain compliance is an important issue to address, with many local retail brands realising that compliance needs to be a top priority to be achieved in order to achieve a globally competitive advantage in the market.

So how do we go about achieving just that?

1. Supply chain visibility – This refers to the data visibility made available within your supply chain; from where your raw materials come from, to your factory’s technical operations right through to your

1. Supply chain visibility – This refers to the data visibility made available within your supply chain; from where your raw materials come from, to your factory’s technical operations right through to your

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

.png)

It is at this point that

It is at this point that A random furniture sample will be selected at this point, where they will each be checked one by one to inspect whether or not they meet the following;

A random furniture sample will be selected at this point, where they will each be checked one by one to inspect whether or not they meet the following;

A social compliance audit can be difficult to attain, but is an absolute necessity for that transparent supply chain your consumers today are demanding.

A social compliance audit ensures that a factory and its practices are abiding by all local laws and that you meet all of the social obligations as set out by the guidelines of the audit, from fair wages to no instances of child labor in a factory.

In this blog post, I will outline the exact procedure of this audit, the benefits it offers to your consumer electronics brand and how you can go about conducting this audit for yourself.

So, let’s dive in…

A social compliance audit can be difficult to attain, but is an absolute necessity for that transparent supply chain your consumers today are demanding.

A social compliance audit ensures that a factory and its practices are abiding by all local laws and that you meet all of the social obligations as set out by the guidelines of the audit, from fair wages to no instances of child labor in a factory.

In this blog post, I will outline the exact procedure of this audit, the benefits it offers to your consumer electronics brand and how you can go about conducting this audit for yourself.

So, let’s dive in…

Document reviews – Auditors will check all the documentation of the supplier to determine the presence of any possible child labour, an all too common violation within the consumer electronics industry. They also assess whether there are any violations of extended working hours and wages. They will also look into what types of social insurance are available to workers and review any fire and safety documentation, which will help to determine whether or not any safety precautions or plans are in place. They will also inspect whether or not there is any environmental monitoring being done and, if so, how it is conducted.

Employee interviews – The auditors conduct interviews with the factory in question staff, where they ask them about their working hours, overtime, and about their holiday/leave time. Auditors also like to cross check these statements by interviewing factory management to ensure there are no discrepancies. This helps to clarify whether there are any instances of abuse or misconduct between staff and management. In the case of a re-audit these interviews will then be conducted again to ensure improvement plans are being implemented properly.

Closing meeting with audit status – This meeting reveals the audit results of your CE factory and also makes suggestion for improvements. If you use

Document reviews – Auditors will check all the documentation of the supplier to determine the presence of any possible child labour, an all too common violation within the consumer electronics industry. They also assess whether there are any violations of extended working hours and wages. They will also look into what types of social insurance are available to workers and review any fire and safety documentation, which will help to determine whether or not any safety precautions or plans are in place. They will also inspect whether or not there is any environmental monitoring being done and, if so, how it is conducted.

Employee interviews – The auditors conduct interviews with the factory in question staff, where they ask them about their working hours, overtime, and about their holiday/leave time. Auditors also like to cross check these statements by interviewing factory management to ensure there are no discrepancies. This helps to clarify whether there are any instances of abuse or misconduct between staff and management. In the case of a re-audit these interviews will then be conducted again to ensure improvement plans are being implemented properly.

Closing meeting with audit status – This meeting reveals the audit results of your CE factory and also makes suggestion for improvements. If you use  In understanding the ethical compliance standards as laid out above, you are able to make informed decisions about the suppliers you choose to use in the manufacturing of your electrical products.

In understanding the ethical compliance standards as laid out above, you are able to make informed decisions about the suppliers you choose to use in the manufacturing of your electrical products.

On 23rd December 2014, the Consumer Product Safety Commission (CPSC) announced the recall of over 7 million coffee machines.Between 2010-2014, there were over 200 complaints of boiling water spraying out of the machine and approximately 90 burn injuries reported.It has been recently announced that Keurig has

On 23rd December 2014, the Consumer Product Safety Commission (CPSC) announced the recall of over 7 million coffee machines.Between 2010-2014, there were over 200 complaints of boiling water spraying out of the machine and approximately 90 burn injuries reported.It has been recently announced that Keurig has  In fact, the inventor today does not get a dime out of the sales of this popular children’s toy, as she was told her idea was not good enough and wouldn’t sell. Needless to say, millions of these toys are sold the world over.

But, she could count that as somewhat of a blessing…

Recently, over

In fact, the inventor today does not get a dime out of the sales of this popular children’s toy, as she was told her idea was not good enough and wouldn’t sell. Needless to say, millions of these toys are sold the world over.

But, she could count that as somewhat of a blessing…

Recently, over