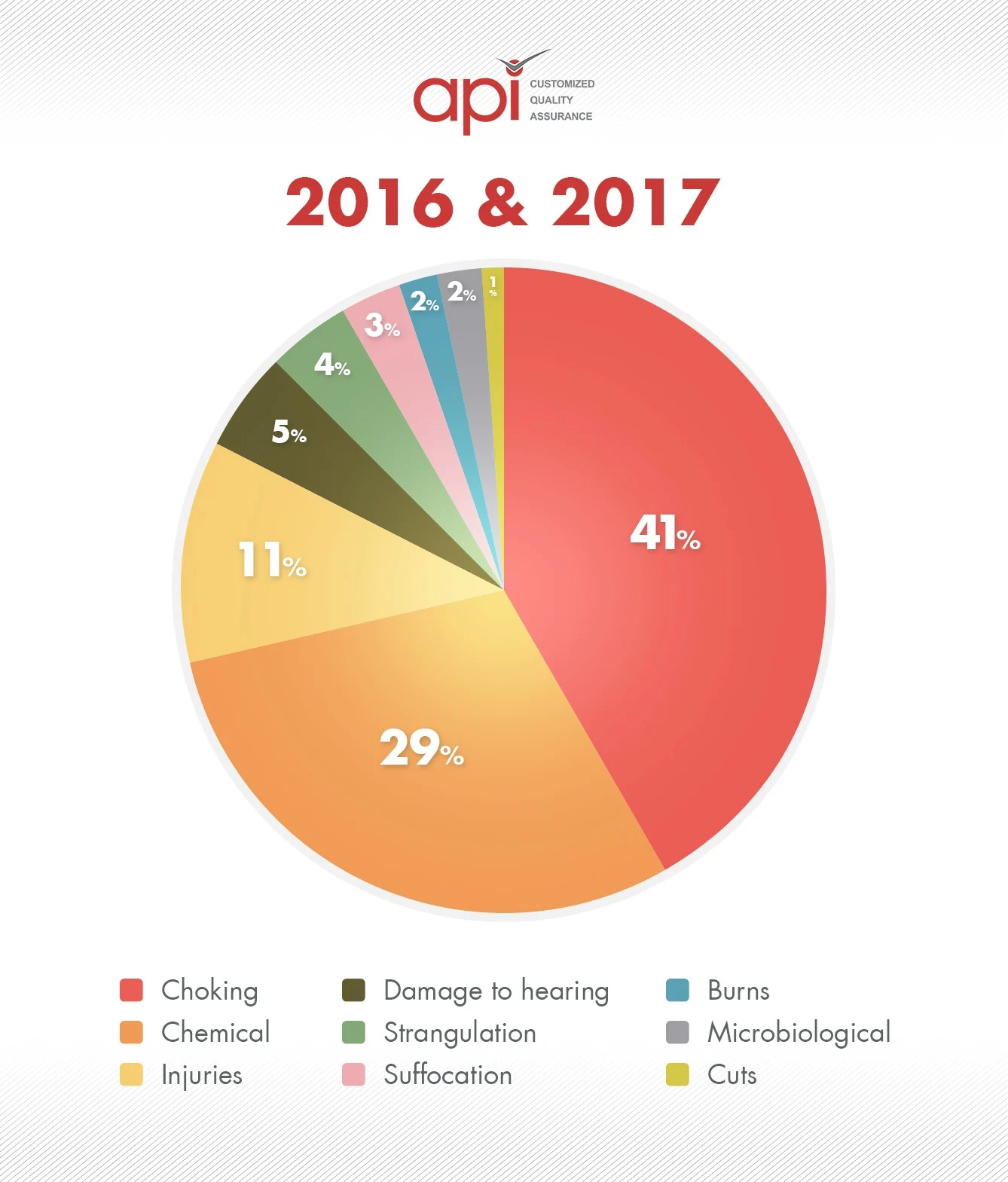

Production competitiveness has become so high in countries like China that suppliers often find ways to cut corners in order to save costs, often putting the quality and safety of your toys, and their extremely vulnerable user base, in jeopardy. When it comes to upholding product safety and compliance, no other consumer goods product is more highly regulated than toys. However, despite stringent requirements and mandatory safety toy testing around the world, unsafe children’s products continue to reach the market today.

As recent as 2017, many importers of the popular ‘fidget spinners’ were found to be selling products in the US that contained alarmingly high levels of mercury and lead leading to mass product recalls and damaged brand reputations.

Non-compliance in the toy industry present a myriad of dangers for brands that can lead to heavy financial losses, unnecessary recalls, and a damaged reputation. It’s reasons like these that quality managers constantly live in fear of quality issues with toys, but it doesn’t have to be this way with strict compliance regulations and proper toy testing procedures.

Improving Your Existing Toy Quality Assurance Processes

As a quality manager who is responsible for producing toys you know that where quality is concerned the stakes are sky-high.

You need to know that toys adhere to the demands of every test they might face when being exported globally to markets with different demands.

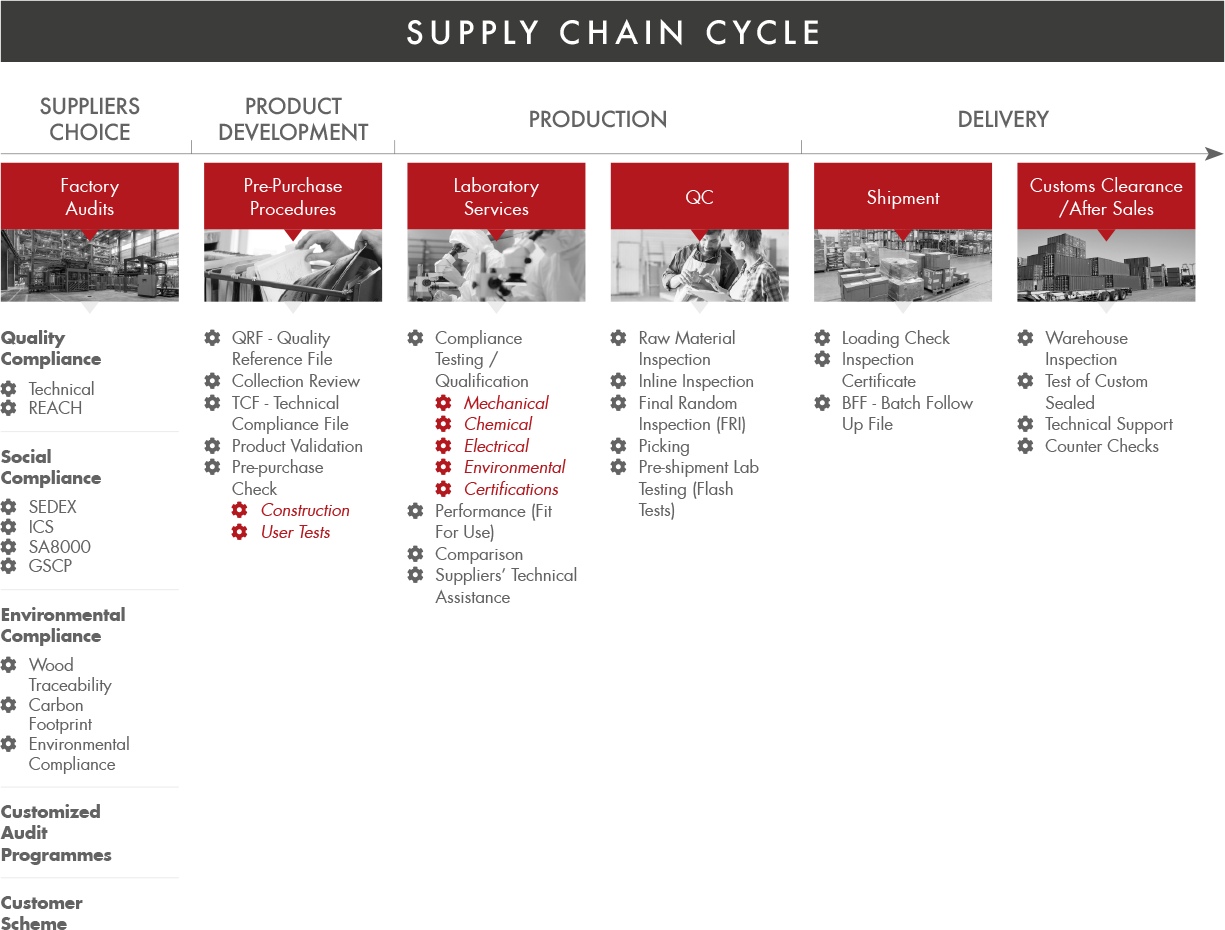

At API, our quality inspectors and laboratories follow a comprehensive set of 8 toy quality testing steps (built through decades of experience) that helps quality managers effectively manage quality right from the outset.

This article will take a brief look at

the global toy testing standards themselves, and the step by step procedures API follows to help minimise the risk of quality issues sneaking through and danger of recalls happening, as well as protecting your supply chain and ensuring customer safety and satisfaction.

API’s 8 Step Toy Quality Assurance Process

Click here to watch our comprehensive toy testing process video

1. Preventing Mechanical Risks In The Design Stage

Product Design Specification (PDS) serves as the guideline for understanding the various problems identified early on in the design stage. Possibilities need to be investigated and filtered through various criteria laid out in the PDS to be set forth as practical, viable solutions that require further evaluation.

Through comprehensive design evaluation and hazard assessments, API help you identify potentially dangerous design features and mechanical risks from the outset, helping you save on costly redesign and engineering resources related to product modification, and more serious quality and safety issues later down the line.

Furthermore, the evaluation also helps to identify all of the necessary tests that you would need to submit your product to.

2. Preventing Toxic Risks With Raw Materials Testing

Raw material quality control is paramount in helping to prevent product failure and ensuring a consistent level of quality that you and your customers expect.

Making sure that players in your supply chain are continuously subjected to testing of raw materials being used in your toy production, or when they decide to switch suppliers, verifies that the materials are at the level of quality you’re paying for and that no toxic elements such as lead and cadmium finding their way into your finished product.

Complying with chemical restrictions in raw materials laid out by the EU and US chemical content regulations such as REACH,

EN71 and CPSIA starts with chemical testing.

API’s laboratories help to identify toxic elements that can aid you in defining a list of approved materials to be used in the toy production process early on, ensuring your products comply with the limits set for safe use now and into the future.

3. Evaluating Toy Safety Before Mass-Production Through Prototype Testing

The practical solutions and tests identified in the design evaluation stage are embodied in the form of a prototype. The aesthetics, functionality, mechanical aspects, as well as the potential manufacturing issues are all considered, and these aspects need to be thoroughly tested.

API’s technical experts are part of technical committees that discuss and write standards for toys, and can ensure you are up to date on the latest developments and discussions on regulation before new regulations are officially published.

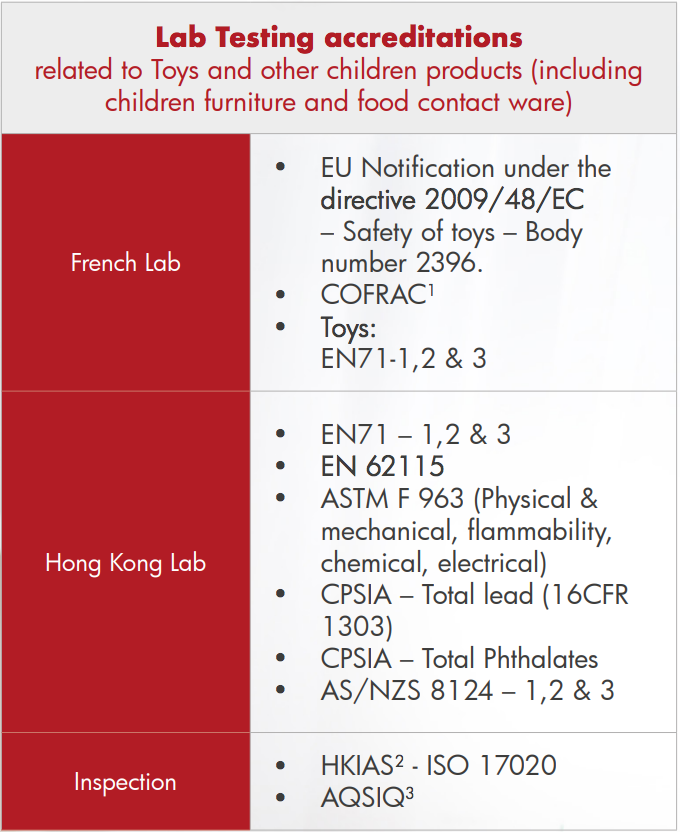

API’s Hong Kong Laboratory is accredited by HOKLAS to perform laboratory testing for the European, American and Australasian markets.

The three main areas of testing are:

1) ‘Mechanical and Physical Properties’

- Drop Test

- Compression Test

- Torque Test

- Tension Test

- Flexure Test

- Bite Test

2) ‘Flammability’

- Conducted on toys to examine their flammability characteristics

3) ‘Restricted Substances – Chemical Testing’

- Lead content test

- Cadmium content test

- Phthalate content test

- Other applicable chemical tests

Prototype testing helps to identify the shortcomings of initial toy design and how they will hold up in real use case scenarios.

Evaluate your Factory

Perform a quality management audit with specific points related to toys, such as ensuring that sharp tool equipment and a broken needle policy has been used and properly calibrated. It is also important to ensure that your factory has also established traceability system for identification and tracking materials through production.

Through this testing process, API helps you to further refine the product design and remove any obstacles that may detract from the original concept by making it safer for use, and ultimately, preventing the need for costly recalls well before the products hit the production line. On top of this testing process, API are also entitled to issue certificates of conformity as a ‘Notified Body’.

4. Ensuring Compliance Through All Inclusive Compliance Software

Whether your brand is directly or indirectly affected by Directive 2009/48/EC, it is of vital importance to ensure the collection and gathering of all the necessary technical documentation needed from your manufacturer to demonstrate the conformity of the product to the applicable requirements of the TSD.

It is up to your product manufacturer to draw up this technical documentation, or request it from relevant parties, and keep it and the EC declaration of conformity for a period of 10 years after the toy has been placed on the market.

It is up to you as the importer to ensure that the manufacturer fulfills this duty, that the toy bears the required conformity marking, and is accompanied by the required technical documents. These documents must be made available to national surveillance authorities upon request for the same period of time to demonstrate conformity of the toy.

Technical documentation to be drawn up and collected must be presented in one of the official languages in the EU and shall include:

1. Description of the design and manufacture

2. List of components and materials

3. Safety data sheets

4. Safety assessments

5. Conformity assessment procedure

6. EC declaration of conformity

7. Addresses of manufacture and storage

8. Documents submitted to a Notified Body

9. Test reports

10. Conformity of series production details

11. EC-type examination details

12. Conformity of series production details

Today, many manufacturers, importers and retailers are still operating on outdated systems like collecting multiple spreadsheets and files, leading to unreliable data and outdated documentation, which creates an almost insurmountable task of trying to accurately trace and maintain the information for each product reference.

API’s Technical Compliance File (TCF) solution is a one process procedure that consists of

5 steps to ensure total product compliance:

1. Expert intervention to define the scope of compliance

2. Document collection

3. Document review

4. TCF report issuance

5. Record keeping and database integration (all available online 24/7)

A solution like this promises increased visibility and transparency into your supply chain that will prove invaluable to optimizing your current quality systems, allowing you the time to mitigate any potential quality risks as and when they become apparent.

5. Monitoring Production Consistency With DUPRO/Inline Inspection

The production line is inspected when at least 25% of the order has been completed. The DUPRO verifies that initial discrepancies found out during an Initial Production Check (IPC) have been rectified.

Each stage of the assembly process will be analysed and samples of the goods in progress will be collected and checked. This means that any impending problem can be identified on-site and addressed at the very stage where it is occurring.

By

checking unfinished products during production and assessing if AQL standards are being met, API assures that corrective actions can be taken in order to assure the quality of your toys moving forward.

6. Checking and Classifying Non-Conformities Right Before Shipping

API conduct both

Final Random Inspections and Loading Check inspections to ensure your products conform and that they are being shipped in a safe and secure manner.

Final Random Inspection

A FRI (Final Random Inspection) is basically an acceptance sampling inspection performed prior to shipment. The Sampling is derived from the inspection level requested in accordance with MIL-STD-105E (ISO2859-1). API is also certified HKIAS which endorses third-party inspection based on an in-house procedure.

The sampled goods are then checked piece by piece and the non-conformities found, if any, will be classified into three categories (critical, major and minor).

The selection of an AQL (Acceptable Quality Level) per type of non-conformities will determine the acceptance or rejection of the goods.

Sample Collection For Lab Testing

Products randomly picked from mass production for pre-shipment testing which can occur in DuPro or FRI. The test checks the alignment of product quality from mass production and pre-production.

Pre-shipment Testing

The aim of pre-shipment testing is to verify the consistency of the production quality with a focus on critical aspects of the toys, without having to perform the full test again.

API provides tailor-made testing solutions based on client requirements to ensure quality is maintained at this stage of the process.

Loading Check Inspections

The loading check serves as a way to control container quantity and to adequately manage stuffing arrangement.

API performs inspections of packed goods as they are being loaded into the shipping container to ensure the correct products are loaded, in a secure and safe manner.

7. Taking Quality Assurance Full Cycle With Reorders and Random Sampling

Sample collection for testing during the reorder process is a concept of a highly effective continuous quality improvement monitoring program, helping you determine the frequency of testing per supplier performance.

This policy sends a clear message to suppliers that you’re watching their product quality closely, and that any unauthorized product/material change is strictly prohibited, and at the same time encourages them to improve.

8. Business Intelligence Tools

In order to the determine the frequency of sampling per factory, you’ll need a comprehensive vendor scorecard. API have developed its own platform for you that records quality data of each factory’s test and defect levels during inspection.

It also provides you with a comprehensive data analysis on factory performance across your own suppliers and across others in our database that you may not currently be working with. The database record does not simply include just the pass or failure of the product test/ inspection, but also a record and classification of each defect.

Through this database we’re able to point out top defects recorded per factory and compare your own suppliers against others in the industry.

More often than not performing an inspection after the production of toys is finished is problematic and too late to rectify any quality problems found within the product.

Enter During Production Inspection (DUPRO).

This inspection type is designed to catch quality issues right on the production line to prevent any delays in getting your product to market.

More often than not performing an inspection after the production of toys is finished is problematic and too late to rectify any quality problems found within the product.

Enter During Production Inspection (DUPRO).

This inspection type is designed to catch quality issues right on the production line to prevent any delays in getting your product to market.

More often than not performing an inspection after the production of toys is finished is problematic and too late to rectify any quality problems found within the product.

Enter During Production Inspection (DUPRO).

This inspection type is designed to catch quality issues right on the production line to prevent any delays in getting your product to market.

More often than not performing an inspection after the production of toys is finished is problematic and too late to rectify any quality problems found within the product.

Enter During Production Inspection (DUPRO).

This inspection type is designed to catch quality issues right on the production line to prevent any delays in getting your product to market.

To minimise the possibility of heavy metal migration in toy manufacturing, the EU has tightened the regulations of toy quality control. Testing according to the revised EN71-3 standard includes 19 elements and the migration limits have been revised. The update has divided toys into three categories:

To minimise the possibility of heavy metal migration in toy manufacturing, the EU has tightened the regulations of toy quality control. Testing according to the revised EN71-3 standard includes 19 elements and the migration limits have been revised. The update has divided toys into three categories:

As a quality manager who is responsible for producing toys you know that where quality is concerned the stakes are sky-high.

You need to know that toys adhere to the demands of every test they might face when being exported globally to markets with different demands.

At API, our quality inspectors and laboratories follow a comprehensive set of 8 toy quality testing steps (built through decades of experience) that helps quality managers effectively manage quality right from the outset.

This article will take a brief look at

As a quality manager who is responsible for producing toys you know that where quality is concerned the stakes are sky-high.

You need to know that toys adhere to the demands of every test they might face when being exported globally to markets with different demands.

At API, our quality inspectors and laboratories follow a comprehensive set of 8 toy quality testing steps (built through decades of experience) that helps quality managers effectively manage quality right from the outset.

This article will take a brief look at  Raw material quality control is paramount in helping to prevent product failure and ensuring a consistent level of quality that you and your customers expect.

Making sure that players in your supply chain are continuously subjected to testing of raw materials being used in your toy production, or when they decide to switch suppliers, verifies that the materials are at the level of quality you’re paying for and that no toxic elements such as lead and cadmium finding their way into your finished product.

Complying with chemical restrictions in raw materials laid out by the EU and US chemical content regulations such as REACH,

Raw material quality control is paramount in helping to prevent product failure and ensuring a consistent level of quality that you and your customers expect.

Making sure that players in your supply chain are continuously subjected to testing of raw materials being used in your toy production, or when they decide to switch suppliers, verifies that the materials are at the level of quality you’re paying for and that no toxic elements such as lead and cadmium finding their way into your finished product.

Complying with chemical restrictions in raw materials laid out by the EU and US chemical content regulations such as REACH,