The state of retail has recently seen an increase in supply chain pressure from retail giants like Amazon that are increasing the pace at which supply chains need to operate.

This increase in pressure and pace mean that your product needs to be on the shelves faster which puts large amounts of strain on your quality procedures, which can result in lower quality products hitting the market.

This is risky.

Quality is complex at the best of times, and as you juggle this increase in pace, it can be difficult to stay on top of the smaller cogs of the quality machine.

So what are retailers doing to avoid potential low quality products?

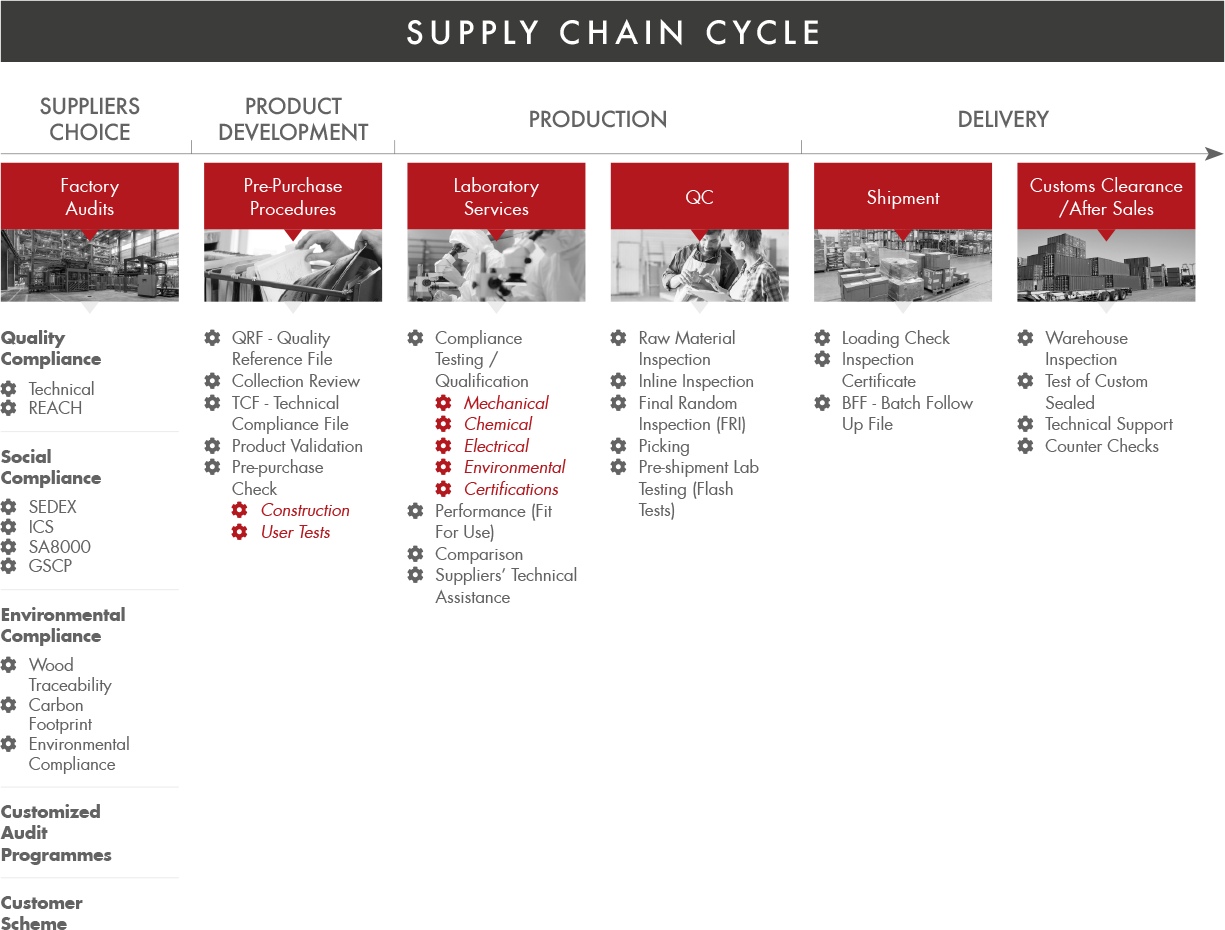

They have begun outsourcing their quality systems to qualified third-party providers to help alleviate some of that supply chain pressure. One of the primary solutions retailers opt for, is a quality audit – to highlight those weak spots within your supply chain and create a plan of action for how you can address them.

In this blog post, we take a look at the purposes of a quality audit for your household goods brand; we take a brief look at what the benefits of outsourcing your quality procedures are and what these benefits can mean for your organization.

Three Ways To Do conduct an Audit

Auditing has become a crucial tool for managing and monitoring the implementation of the quality systems of many factories. Let’s take a look at the three ways that these audits can be performed;- In-house audit – This is performed internally by an in-house team. They measure the strengths and weakness of quality and production systems against any international/external standards and regulation. This form of auditing is unable to provide your organization with any form of certification.

- Second-party audit – This is when an organization performs an audit of their potential supplier, to ensure that they can meet your production requirements. Often these audits can be completed onsite to review the internal technical processes of the supplier, but this audit can also be performed off-site in the form of documentation reviews. It will be up to your organization to define what exactly you want to audit to help you make a well-informed decision about your supplier. This type of audit has nothing to do with QMS certification, as only a registered third-party auditing organization can provide this.

- Third-party audit – This is conducted by a qualified audit organization, that is not connected to the supplier or brand by any nature. M

any organizations consider third-party audits for many reasons, mainly they have come to the decision to create a quality management system (QMS) such as ISO 9001. A third-party auditor would come in and assess whether or not this organization meets the requirements as laid out by the above QMS. A third-party auditor will then provide your organization with a certification stipulating that you meet the requirements as laid out. This is often a preferred audit option as the results are unbiased and certification has become a competitive differentiator.

any organizations consider third-party audits for many reasons, mainly they have come to the decision to create a quality management system (QMS) such as ISO 9001. A third-party auditor would come in and assess whether or not this organization meets the requirements as laid out by the above QMS. A third-party auditor will then provide your organization with a certification stipulating that you meet the requirements as laid out. This is often a preferred audit option as the results are unbiased and certification has become a competitive differentiator.

The Purposes Of A Quality Audit For Your Brand

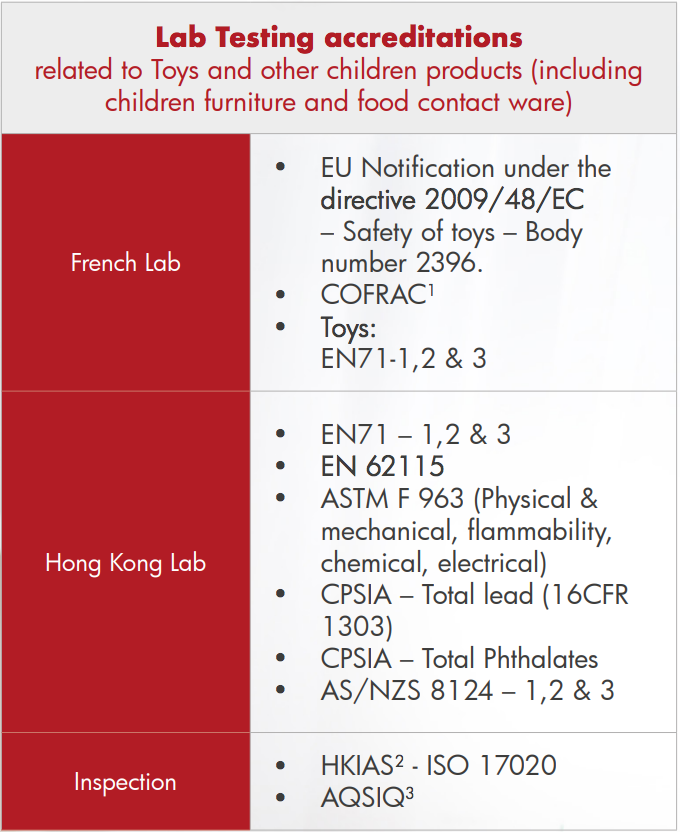

In defining the purpose of an audit for your brand, you will be able to understand who should be conducting your audit. The main objectives are as follows;- Certification – Many household goods retailers that produce a product that contains high levels of risk, such as toys and electrical appliances, etc. and are wanting to do business in Europe will need to comply with the CE directive as laid out the European Commission. The management system of your supplier will need to be assessed according to any one of the ISO standards and the certified accordingly. Bear in mind that the auditing company you choose to use will need to be certified by a regulatory body to certify you.

- Performance versus compliance/conformance audits – Many audits have different purposes. It will be important to try and make sure that if you are performing an internal audit, that you keep it as holistic as you possibly can. Your audit will need to assess compliance and performance. The audit report will need to identify the suppliers standing according to both of these categories.

- Follow-up audit – An audit will often present findings that will need time to rectify, in which a follow-up will be needed to ensure that corrective actions have taken place.

The five benefits of using a third-party quality auditor

If you are unsure of the benefits that a third-party quality provider can provide you take a quick look here;- Expertise – Third-party auditors undergo formal auditing training and experience to notice noncompliance and unethical situations. This wealth of knowledge and experience will be of benefit to your organization.

- Efficiency – A third-party auditor has the infrastructure to ensure they meet your organization’s auditing needs.

- Technology – They have the appropriate tools and technology to ensure a successful audit of your supplier.

- Accountability – A third-party auditor will have pledged to uphold a certain code of ethical conduct and are held accountable to the greater company policies, rules, and regulations.

- Risk Reduction – A third-party auditor is trained to identify mishappenings within the quality systems of a potential supplier. This insight allows you to manage risk early on.

Both of these retailers experienced significant challenges within their supply chains, one had even previously adopted the services of a 3rd party QA provider, who made no strides in overcoming their challenges with them.

Both of these retailers experienced significant challenges within their supply chains, one had even previously adopted the services of a 3rd party QA provider, who made no strides in overcoming their challenges with them. More often than not performing an inspection after the production of toys is finished is problematic and too late to rectify any quality problems found within the product.

Enter During Production Inspection (DUPRO).

This inspection type is designed to catch quality issues right on the production line to prevent any delays in getting your product to market.

More often than not performing an inspection after the production of toys is finished is problematic and too late to rectify any quality problems found within the product.

Enter During Production Inspection (DUPRO).

This inspection type is designed to catch quality issues right on the production line to prevent any delays in getting your product to market.

The quality of a product can be defined in many ways and is almost always dependent on your specific consumer and their definition of quality for your specific item. So in that light, you will need to know exactly what your consumer is looking for to create the quality your brand is looking to achieve.

When a consumer sets out to look for a quality product, they want to feel as though they have paid less than what the actual product is worth, the quality of the product far surpassing the amount they ended up paying. Fulfilling the need to exceed the consumer’s expectations, this is what true quality is all about.

If fulfilling the need to meet your consumer’s expectations is at the top of your company’s agenda, is it not essential for your brand’s products to meet a level of quality that does just that? Let me leave you pondering that for a bit.

In attempting to understand your customer’s definition of quality, it will be important to note that fulfilling consumer expectation and experience forms a part of that definition.

Let me give you an example; If a consumer orders a product that has met and passed all quality tests it needed to meet, that product for all intents and purposes is a quality item. But, if the order arrives later than promised or arrives with a missing screw or the incorrect color, the consumer may not define this product as an item of value and quality.

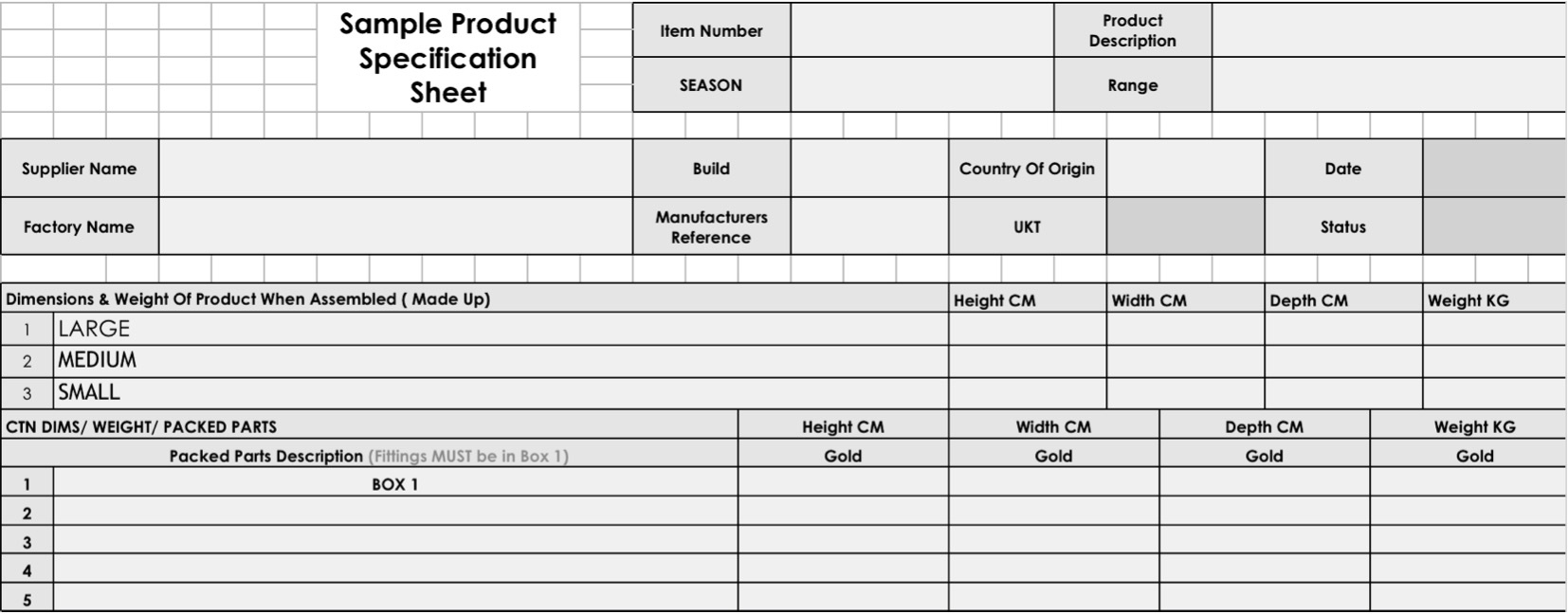

Striving for product quality is a stems right from the raw materials used, to the way in which it arrives to your customer, therefore every step needs to be taken into consideration.

The quality of a product can be defined in many ways and is almost always dependent on your specific consumer and their definition of quality for your specific item. So in that light, you will need to know exactly what your consumer is looking for to create the quality your brand is looking to achieve.

When a consumer sets out to look for a quality product, they want to feel as though they have paid less than what the actual product is worth, the quality of the product far surpassing the amount they ended up paying. Fulfilling the need to exceed the consumer’s expectations, this is what true quality is all about.

If fulfilling the need to meet your consumer’s expectations is at the top of your company’s agenda, is it not essential for your brand’s products to meet a level of quality that does just that? Let me leave you pondering that for a bit.

In attempting to understand your customer’s definition of quality, it will be important to note that fulfilling consumer expectation and experience forms a part of that definition.

Let me give you an example; If a consumer orders a product that has met and passed all quality tests it needed to meet, that product for all intents and purposes is a quality item. But, if the order arrives later than promised or arrives with a missing screw or the incorrect color, the consumer may not define this product as an item of value and quality.

Striving for product quality is a stems right from the raw materials used, to the way in which it arrives to your customer, therefore every step needs to be taken into consideration.

craze of fidget spinners and, where 200, 000 of these spinners have been recalled due to it

craze of fidget spinners and, where 200, 000 of these spinners have been recalled due to it  they want to know where its raw materials were sourced, how it was made, who made it and what its level of quality is. They ask themselves whether or not your product will be an investment in their lives.

The key here will be to know your target market, know your consumer. If you do not know what they want, you will struggle to be their go-to brand; you will lose out on their brand evangelism and praise affecting your bottom line

“Is this the type of brand and product you wish to create?”

Retailers today are under so much pressure with the current supply and demand of products, that quality and/or compliance is not always a priority.

“But, it should be!”

Bad quality and non-compliance both mean that your brand is at an unnecessarily high risk with regards to meeting regulations and your reputation. It will be worth all the hard yards that you put in from the creation and design to the manufacturing and distribution of your products. This will help mitigate unnecessary risk, saving you money and precious time.

they want to know where its raw materials were sourced, how it was made, who made it and what its level of quality is. They ask themselves whether or not your product will be an investment in their lives.

The key here will be to know your target market, know your consumer. If you do not know what they want, you will struggle to be their go-to brand; you will lose out on their brand evangelism and praise affecting your bottom line

“Is this the type of brand and product you wish to create?”

Retailers today are under so much pressure with the current supply and demand of products, that quality and/or compliance is not always a priority.

“But, it should be!”

Bad quality and non-compliance both mean that your brand is at an unnecessarily high risk with regards to meeting regulations and your reputation. It will be worth all the hard yards that you put in from the creation and design to the manufacturing and distribution of your products. This will help mitigate unnecessary risk, saving you money and precious time.

A POA is essential for filling out shippers exportation documents. This exportation document cannot be completed without a valid POA. Without it, your shipment will not be released, costing you time and money.

“So, what happens when one of these documents are not in order?”

You incur costs that begin adding up on a daily basis. Your shipment will be warehoused, where you will be billed for every day your shipment is there. It will be time consuming. Much of the paperwork mentioned above takes time to complete, but now you will be waiting on paperwork while raking up warehouse fees. This is not an ideal situation but can be avoided with thorough, well-kept, organized paperwork and a dash of patience to go along with it.

A POA is essential for filling out shippers exportation documents. This exportation document cannot be completed without a valid POA. Without it, your shipment will not be released, costing you time and money.

“So, what happens when one of these documents are not in order?”

You incur costs that begin adding up on a daily basis. Your shipment will be warehoused, where you will be billed for every day your shipment is there. It will be time consuming. Much of the paperwork mentioned above takes time to complete, but now you will be waiting on paperwork while raking up warehouse fees. This is not an ideal situation but can be avoided with thorough, well-kept, organized paperwork and a dash of patience to go along with it.

will provide an easier platform to discuss these matters in-depth, with absolute understanding and clarity. Personally I find Zoom a favorite for all conference calling, it has helped me stay in touch with a lot more ease than just relying on email.

Now that we have spoken about the means of communication, we need to address the frequency and manner of communication.

“How often do you phone your supplier to just talk about basic business operations?”

The more constant the flow of communication is, the more you will begin to get to know your supplier, and where your business sits in the grander scheme of their operations (and how much they stand to lose if they make mistakes).

This level of trust that you begin to build with your supplier will help to keep them honest and accountable if you happen to receive a delivery of products that are non compliant.

This kind of communication provides clarity and indicates to your supplier that you trust them to fix the problem to achieve the level of compliance that your company has set as the standard.

will provide an easier platform to discuss these matters in-depth, with absolute understanding and clarity. Personally I find Zoom a favorite for all conference calling, it has helped me stay in touch with a lot more ease than just relying on email.

Now that we have spoken about the means of communication, we need to address the frequency and manner of communication.

“How often do you phone your supplier to just talk about basic business operations?”

The more constant the flow of communication is, the more you will begin to get to know your supplier, and where your business sits in the grander scheme of their operations (and how much they stand to lose if they make mistakes).

This level of trust that you begin to build with your supplier will help to keep them honest and accountable if you happen to receive a delivery of products that are non compliant.

This kind of communication provides clarity and indicates to your supplier that you trust them to fix the problem to achieve the level of compliance that your company has set as the standard.

importers that do not pay on time so as to avoid those kinds of risks for themselves in the future.

What is advisable with regards to payment is ensuring that you have laid out all your payment terms with your supplier. In doing this you create a level of transparency with your supplier which can prove to be invaluable.

If you have been in this position before, as I am sure you have, I would say that the best practice here would be the same as tip #1;

Communication

You need to communicate your situation immediately, creating an honest and open relationship with your supplier which will put you in good stead for future orders.

importers that do not pay on time so as to avoid those kinds of risks for themselves in the future.

What is advisable with regards to payment is ensuring that you have laid out all your payment terms with your supplier. In doing this you create a level of transparency with your supplier which can prove to be invaluable.

If you have been in this position before, as I am sure you have, I would say that the best practice here would be the same as tip #1;

Communication

You need to communicate your situation immediately, creating an honest and open relationship with your supplier which will put you in good stead for future orders.

This knowledge creates an improvement in their service to you as operational times and

This knowledge creates an improvement in their service to you as operational times and

To minimise the possibility of heavy metal migration in toy manufacturing, the EU has tightened the regulations of toy quality control. Testing according to the revised EN71-3 standard includes 19 elements and the migration limits have been revised. The update has divided toys into three categories:

To minimise the possibility of heavy metal migration in toy manufacturing, the EU has tightened the regulations of toy quality control. Testing according to the revised EN71-3 standard includes 19 elements and the migration limits have been revised. The update has divided toys into three categories: