The sustainability mega-trend hasn’t missed the toy market. Today’s eco-conscious consumers have put toy makers under pressure to produce products that are sustainable, but the reality is that very few toys can be recycled. Most are made from a combination of plastics, metals, and other components that most recycling companies don’t accept. To put a number to it, experts suggest that the toy industry alone is on track to produce more than one million tons of plastic waste annually from 2023. In the face of this staggering plastics problem, the sustainable toy market is growing, valued at US$19 million in 2020 and forecast to reach US$60 million by 2030.

Environmental responsibility isn’t the only driving force behind the rise of green toys. Consumers have become more aware of the health effects of toxic chemicals and materials found in products intended for children and are demanding alternatives. Technological and material innovations have also advanced the sustainability quest, but obstacles remain in sourcing and testing. Furthermore, a combination of kids being stuck at home and eco-anxiety caused by the pandemic has accelerated consumer appetite for made-to-last, planet-friendly toys.

Many of the major players in the toy industry are leading the way to reduce the environmental impact of toys. The Lego Group is on a challenging mission to make all its core products out of sustainable materials by 2030, and by 2025, all its packaging will be made from renewable or recycled materials. The brand has also introduced an initiative (Lego Replay) that invites children to donate their pre-loved Lego bricks to children in need. Mattel Inc. has expanded its Mattel Playback program, which allows consumers to send back a broad range of Mattel toys for recycling and reuse. The brand has also introduced certified carbon-neutral toys and aims to use entirely recycled, recyclable, or bio-based plastics in all its toys and packaging by 2030.

Consumers naturally expect safe products from the brands they trust—especially those targeting children. When implementing sustainable materials and processes, toy brands must ensure that they’re not introducing products that may be dangerous for children. Toxic chemicals in toys are of particular concern, especially those made for kids under 3 because of their mouthing and rapid metabolic rate, high surface area to body weight ratio, and rapid physical development. The product safety risks of toys made with sustainability in mind include:

Most toy safety testing relates to chemicals, and any substances found to be potentially damaging to human health are immediately banned from the industry. Regulation in this area is increasing and becoming more expensive and challenging to navigate. A third-party expert can help you determine which tests are required based on your BOM and materials and work with you to streamline the testing process. This will not only enable you to stay ahead of regulations and avoid costly risks but will, most importantly, put your customers’ health and wellbeing first. It will also give you visibility over your supply chain so you can anticipate and manage risks throughout the product life cycle.

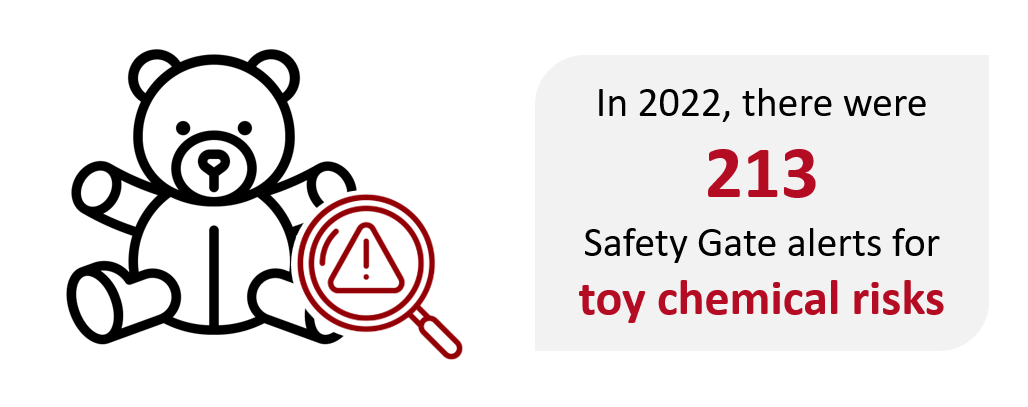

Missteps can be costly, and they do happen. In 2022, 213 toy products were recalled in Europe because of chemical risks.

By not actively managing your chemical risks, you risk a lot more: your brand reputation. After consumer trust satisfaction plummets, it can be a tall and expensive mountain to climb to win that trust back—especially for toy companies that are perceived to not care about the wellbeing of children. Mattel Inc., the largest brand in the US, recalled millions of toys in 2007 due to hazards from small, powerful magnets and lead paint. The recall costs and lawsuits have cost the brand over US$100 million, but the damage to brand reputation may cost them for many years to come.

How can toy brands align their sustainability efforts with the importance of product safety? Compliance is essential, but it’s only the starting block. Supply chain visibility, improved traceability, and scientific methods that help verify the origin of new materials and the potential presence of harmful substances can help you anticipate risks early on and focus on the areas where risks are highest, ultimately saving you time and money.

Chemical Risk Assessment is the identification and mapping of product risks based on:

This risk-based approach allows you to maximize safety while managing costs.

At API, we combine our on-the-ground experience with our scientific expertise in an end-to-end approach, allowing you to create more sustainable products that are still safe to use. Some of our specialized solutions include:

Interested in finding out more about how our safety solutions can benefit your brand?

Want to know more about one of our many services? Contact us to find out more information about what API can do for your company today.

Address

Copyright © 1981 – 2022 API. All Rights Reserved.