API performs product inspections services according to recognized international quality standard for product inspections: ISO 2859-1 (ANSI/ASQC Z1.4-2003), also known as the AQL Tables. Clients may request us to use an alternative standard if they have special requirements.

Inspection process

What do we inspect during an inspection?

- The quantity produced (semi-finished, finished and packed)

- The visual appearance (cosmetic check of the mass production)

- The product specifications (size, dimensions, colors)

- The labeling and marking

- The packing and packaging

- All possible functions and possible tests (safety, abuse, printing, etc.)

What quality standards do we use for product inspections?

Based on the acceptable quality limit sampling size chosen from the AQL tables, we carefully ensure to select random production samples. We inspect each sample and classify the defects into critical, major and minor defects. We use detailed product checklists for these definitions. Your are invited to make amendments if there are any product-specific issues we need to take into account.

According to the number of defects found for each type, we will advise you to accept or to reject your shipment. You can then make your own decision based on the detailed report we have provided, discuss the findings with your vendor, ask him to rework, re-produce or sort out the defective products.

How to use the AQL tables?

The AQL tables are incorporated into international quality standards to help ensure product quality meets your expectations.

The tables will determine the sampling size we inspect according to your order quantity and your Acceptable Quality Tolerance level (I, II or III). The standard AQL sampling plan used by 98% of the people is the level II for a normal product inspections.

If your order has multiple references, we should ideally perform a level II inspection on each reference, at the minimum.

For a standard order, the standard level II from the AQL gives the minimum sampling size we should check per reference if you do not want to take additional risks. If we inspect a general level II sampling size on multiple references orders, then the sampling size is diluted and divided by the number of references, increasing the risks as the sampling size must not be representative enough. More information about:

- How to use the AQL table

- Choosing the right AQL inspection level

How to find your sampling size on the AQL table?

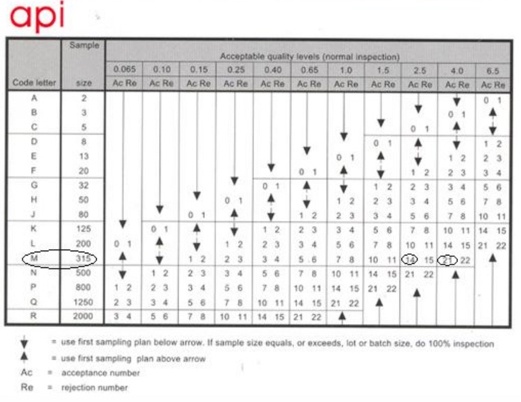

To find the AQL sampling size for inspection, we look at the first chart and locate the range of total items produced on the left side. You have the choice of levels I, II and III, with Level III being the most stringent testing and level I being the least. Level II is the standard and is most commonly used. For example, if you are producing 8,000 items, at level II that results in the letter L which in turn corresponds to the inspection of 200 items in the second table.

On the top of the second AQL chart, you can find the defect levels, ranging from 0 to 6.5. Choose which level to apply to each type of defect: critical, major, and minor. Most importers usually choose standard defect levels which are 0/2.5/4, but you can pick 1/1/1 or 0/1.5/2.5 for high-risk products such as those in the automotive industry. Using the standard 0/2.5/4 defect levels and a sample size of 200, we see that if you have more than 0 critical defects, 10 major defects, or 14 minor defects, you should reject your shipment. Of course, the decision about what to do after your received the inspection results belongs to you. Most importers discuss all inspection findings with their vendor/manufacturer to improve wherever possible.

In case the inspection results are very close to AQL limits, it is important that you double check if the level of found defects is acceptable to you or not.

You can also use our AQL Calculator to define the sample size you need.