Despite significant efforts to contain the spread and global impact of COVID-19, the situation has worsened, affecting people and companies all around the globe. The full implications of COVID-19 on the supply chain remain difficult to predict, with some areas slowly returning to activity while others are now being adversely affected by the virus. It is, however, possible to see that, at this stage, the crisis is having a direct influence on the supply chain, from raw materials to finished products.

As a company with a strong presence on the ground, visiting factories every day, we at API have seen first-hand some of the challenges that brands and retailers are facing in their supply chain. We are helping our customers and their suppliers brace for the impact this extraordinary crisis has had, and continues to have, on their supply chain, providing them with short-term solutions that will help them maintain high quality in their processes and goods while ensuring that the people on the ground remain safe.

Supply Chain Challenges

We were confronted with the gravity of the crisis during the first peak of the virus in China, where some factories were unreachable, production stopped, goods were unable to be shipped, etc. Now that activity is resuming in this part of the world, the challenges have evolved, resulting in many companies putting the quality of their products at risk. It is important to bear in mind that these challenges will most likely be replicated in other manufacturing areas when activity resumes. Therefore, a sound understanding of those issues now might allow for quicker reactions in some of your other sourcing locations. Among them are:

This crisis may be the catalyst to revisit the global supply chain strategy and accelerate the adoption of new models and capabilities, but in the meantime short-term actions are needed to respond to the challenge.

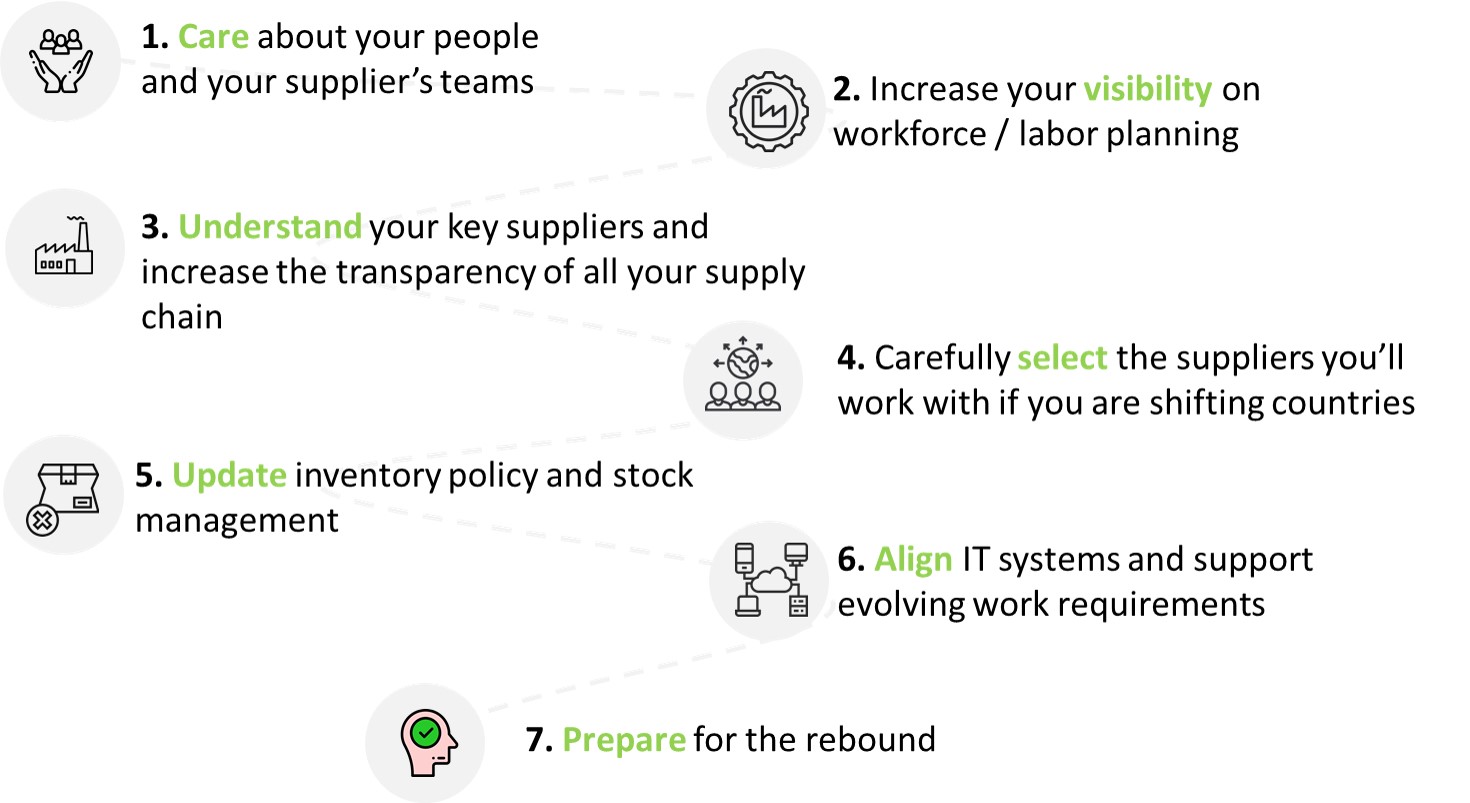

Here are some tips from a manufacturing perspective to help with the continuity of your supply chain while maintaining quality products:

Training and specific audits that focus on the measures to be adopted during this crisis are a good tool to ensure the health and safety of the teams.

Data collection here is key: from gathering the records of the factories for a quick screening, to implementing more in-depth measures such as technical audits, in-line inspections or in-production assessment, having greater visibility of the real situation of your factories is vital at this stage to not only ensure the completion of your production on time but also the quality of the goods delivered.

Whether your orders only represent a small portion of one factory’s production lines or you are flooding these same production lines with your goods makes a huge difference as to how to interact with this factory. If you are not a key customer, you need to make sure you understand how the factory will be dealing with your order when/if they face a shortage of staff or inventory.

The concept of shifting production to other areas was already on the table before the virus appeared, with a trend among many companies toward considering moving ‘out of China’. Diversifying areas of production and looking for alternative locations can help secure additional inventory and capacity. However, launching production in a new area can be challenging if you don’t have the experience or the right teams in that specific area. A third-party company can support you with adapted solutions to facilitate the transition and ensure the quality of your production through a dedicated technician program.

This might lead to associated risks such as product deterioration or mold development which can be identified via a final inspection and tackled with a warehouse condition audit or a more elaborate mold prevention program.

We are being forced to shift from a culture of ‘on-site’ work to ‘remote work’. Be ready to embrace change and to consider possibilities that were not even contemplated a few months ago, such as video-monitored inspections.

For brands, retailers and importers’ quality management teams, online quality management solutions can help manage your goods’ quality even when working from home. With a simple click of the mouse, it is now possible to keep track of your quality actions, read reports and make decisions on whether or not the goods should be shipped. Expert technicians are also one video/phone call away, offering their support in these difficult times and finding the best possible solutions to cope with the crisis.

We are, without doubt, facing exceptional times and although it is impossible to anticipate when and how this epidemic will pass, we need to remain confident, align our efforts and prepare for a brighter future. Stay alert and ready for change: those that are able to adjust quickly will have a higher chance of rebounding and adapting to the times ahead.

At API we are putting our manufacturing experience and product expertise at the disposal of our clients to help them adjust during this difficult time. Thanks to the agility and flexibility of our teams and our local infrastructure we are able to quickly implement on-site and remote solutions to respond to our clients’ needs.

Do not hesitate to get in touch with us to discuss your supply chain challenges.

Want to know more about one of our many services? Contact us to find out more information about what API can do for your company today.

Address

Copyright © 1981 – 2022 API. All Rights Reserved.