Der Zustand des Einzelhandels hat in letzter Zeit eine Zunahme des Drucks in der Lieferkette von Einzelhandelsriesen wie Amazon, die das Tempo, mit dem die Lieferketten arbeiten müssen, erhöhen.

Diese Zunahme des Drucks und des Tempos bedeutet, dass Ihr Produkt schneller in den Regalen sein muss, was Ihre Qualitätsverfahren stark belastet, was dazu führen kann, dass Produkte von geringerer Qualität auf den Markt kommen.

Das ist riskant.

Qualität ist in den besten Zeiten ein komplexes Thema, und während Sie mit dem erhöhten Tempo jonglieren, kann es schwierig sein, den Überblick über die kleineren Rädchen der Qualitätsmaschine zu behalten.

Was tun die Einzelhändler also, um potenziell minderwertige Produkte zu vermeiden?

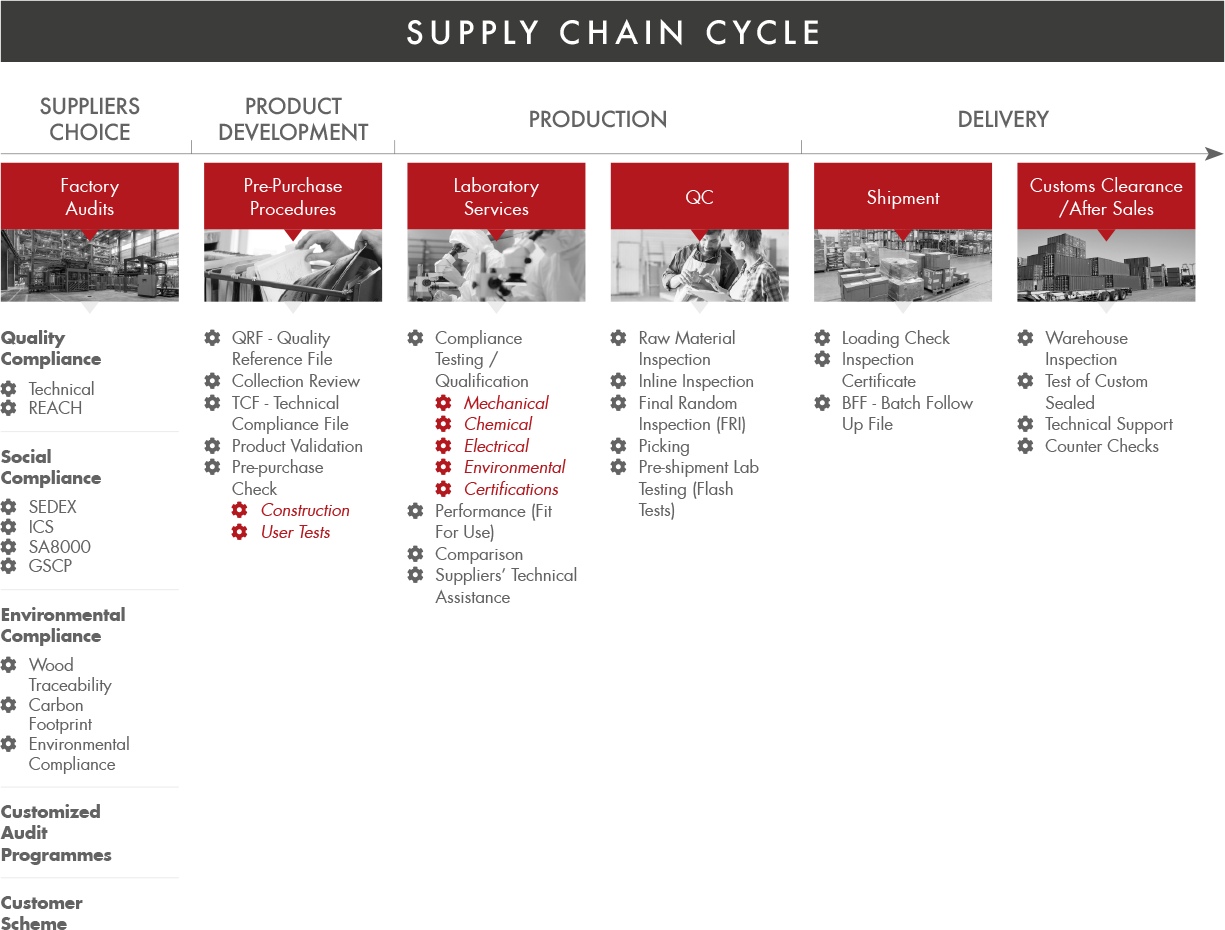

Sie haben begonnen Auslagerung ihrer Qualitätssysteme auf qualifizierte Drittanbieter zurückgreifen, um den Druck in der Lieferkette zu mindern. Eine der wichtigsten Lösungen, für die sich Einzelhändler entscheiden, ist ein Qualitätsaudit - um die Schwachstellen in Ihrer Lieferkette aufzuzeigen und einen Aktionsplan zu erstellen, wie Sie diese beheben können.

In diesem Blogbeitrag werfen wir einen Blick auf den Zweck von ein Qualitätsaudit für Ihre HaushaltswarenmarkeIm Folgenden werden die Vorteile des Outsourcings Ihrer Qualitätsverfahren kurz erläutert und was diese Vorteile für Ihr Unternehmen bedeuten können.

Drei Wege zur Durchführung eines Audits

Audits sind zu einem wichtigen Instrument für die Verwaltung und Überwachung der Umsetzung von Qualitätssystemen in vielen Betrieben geworden. Werfen wir einen Blick auf die drei Arten, wie diese Audits durchgeführt werden können;- Interne Prüfung - Dies wird intern von einem internen Team durchgeführt. Sie messen die Stärken und Schwächen von Qualitäts- und Produktionssystemen anhand internationaler/externer Normen und Vorschriften. Diese Form des Audits kann Ihrem Unternehmen keine Zertifizierung verschaffen.

- Prüfung durch eine zweite Partei - Dabei führt ein Unternehmen ein Audit bei seinem potenziellen Lieferanten durch, um sicherzustellen, dass dieser Ihre Produktionsanforderungen erfüllen kann. Häufig können diese Audits vor Ort durchgeführt werden, um die internen technischen Prozesse des Lieferanten zu überprüfen, aber dieses Audit kann auch außerhalb des Unternehmens in Form von Dokumentationsprüfungen durchgeführt werden. Es hängt von Ihrem Unternehmen ab, was genau Sie prüfen wollen, um eine fundierte Entscheidung über Ihren Lieferanten zu treffen. Diese Art von Audit hat nichts mit einer QMS-Zertifizierung zu tun, da diese nur von einer registrierten, unabhängigen Prüforganisation durchgeführt werden kann.

- Prüfung durch Dritte - Dies wird von einer qualifizierten Prüforganisation durchgeführt, die in keiner Weise mit dem Lieferanten oder der Marke verbunden ist. M

Organisationen ziehen Audits durch Dritte aus vielen Gründen in Betracht, vor allem aber, weil sie beschlossen haben, ein Qualitätsmanagementsystem (QMS) wie ISO 9001 einzuführen. Ein unabhängiger Prüfer kommt und bewertet, ob die Organisation die Anforderungen des oben genannten QMS erfüllt oder nicht. Ein unabhängiger Prüfer wird Ihrer Organisation dann eine Zertifizierung ausstellen, die besagt, dass Sie die festgelegten Anforderungen erfüllen. Dies ist häufig eine bevorzugte Auditoption, da die Ergebnisse unvoreingenommen sind und die Zertifizierung zu einem Unterscheidungsmerkmal im Wettbewerb geworden ist.

Organisationen ziehen Audits durch Dritte aus vielen Gründen in Betracht, vor allem aber, weil sie beschlossen haben, ein Qualitätsmanagementsystem (QMS) wie ISO 9001 einzuführen. Ein unabhängiger Prüfer kommt und bewertet, ob die Organisation die Anforderungen des oben genannten QMS erfüllt oder nicht. Ein unabhängiger Prüfer wird Ihrer Organisation dann eine Zertifizierung ausstellen, die besagt, dass Sie die festgelegten Anforderungen erfüllen. Dies ist häufig eine bevorzugte Auditoption, da die Ergebnisse unvoreingenommen sind und die Zertifizierung zu einem Unterscheidungsmerkmal im Wettbewerb geworden ist.

Die Ziele eines Qualitätsaudits für Ihre Marke

Bei der Definition der Zweck einer Prüfung für Ihre Marke, können Sie verstehen, wer Ihr Audit durchführen sollte. Die wichtigsten Ziele sind die folgenden;- Zertifizierung - Viele Haushaltswarenhändler, die Produkte mit hohem Risikopotenzial herstellen, wie z. B. Spielzeug und Elektrogeräte, und die in Europa tätig werden wollen, müssen die CE-Richtlinie der Europäischen Kommission einhalten. Das Managementsystem Ihres Lieferanten muss nach einer der ISO-Normen bewertet und entsprechend zertifiziert werden. Bedenken Sie, dass das von Ihnen gewählte Prüfungsunternehmen von einer Aufsichtsbehörde zertifiziert sein muss, um Sie zu zertifizieren.

- Wirtschaftlichkeitsprüfungen im Gegensatz zu Konformitäts- und Regelmäßigkeitsprüfungen - Viele Audits haben unterschiedliche Ziele. Wenn Sie ein internes Audit durchführen, sollten Sie darauf achten, dass Sie es so ganzheitlich wie möglich gestalten. Bei Ihrem Audit müssen Sie die Einhaltung der Vorschriften und die Leistung bewerten. Im Auditbericht müssen die Lieferanten nach diesen beiden Kategorien eingestuft werden.

- Follow-up-Audit - Bei einer Prüfung werden häufig Feststellungen gemacht, die erst nach einer gewissen Zeit behoben werden können. In diesem Fall ist ein Follow-up erforderlich, um sicherzustellen, dass Abhilfemaßnahmen ergriffen wurden.

Die fünf Vorteile des Einsatzes eines externen Qualitätsprüfers

Wenn Sie sich nicht sicher sind, welche Vorteile Ihnen ein externer Qualitätsanbieter bieten kann, werfen Sie einen kurzen Blick auf diese Seite;- Fachwissen - Die externen Prüfer haben eine formale Prüfungsausbildung und Erfahrung, um Verstöße und unethische Situationen zu erkennen. Dieser Wissens- und Erfahrungsschatz wird Ihrer Organisation von Nutzen sein.

- Effizienz - Ein externer Prüfer verfügt über die nötige Infrastruktur, um die Prüfungsanforderungen Ihres Unternehmens zu erfüllen.

- Technik - Sie verfügen über die geeigneten Instrumente und Technologien, um ein erfolgreiches Audit bei Ihrem Lieferanten zu gewährleisten.

- Rechenschaftspflicht - Ein externer Prüfer hat sich verpflichtet, einen bestimmten ethischen Verhaltenskodex einzuhalten, und ist für die Einhaltung der übergeordneten Unternehmensrichtlinien, Regeln und Vorschriften verantwortlich.

- Risikominderung - Ein unabhängiger Prüfer ist darin geschult, Missstände in den Qualitätssystemen eines potenziellen Lieferanten zu erkennen. Dieser Einblick ermöglicht es Ihnen, Risiken frühzeitig zu steuern.

Beide Einzelhändler sahen sich innerhalb ihrer Lieferketten mit erheblichen Problemen konfrontiert, einer von ihnen hatte sogar zuvor die Dienste eines externen QS-Anbieters in Anspruch genommen, der jedoch keine Fortschritte bei der Bewältigung der Probleme mit ihnen machte.

Beide Einzelhändler sahen sich innerhalb ihrer Lieferketten mit erheblichen Problemen konfrontiert, einer von ihnen hatte sogar zuvor die Dienste eines externen QS-Anbieters in Anspruch genommen, der jedoch keine Fortschritte bei der Bewältigung der Probleme mit ihnen machte. More often than not performing an inspection after the production of toys is finished is problematic and too late to rectify any quality problems found within the product.

Enter During Production Inspection (DUPRO).

This inspection type is designed to catch quality issues right on the production line to prevent any delays in getting your product to market.

More often than not performing an inspection after the production of toys is finished is problematic and too late to rectify any quality problems found within the product.

Enter During Production Inspection (DUPRO).

This inspection type is designed to catch quality issues right on the production line to prevent any delays in getting your product to market.

The quality of a product can be defined in many ways and is almost always dependent on your specific consumer and their definition of quality for your specific item. So in that light, you will need to know exactly what your consumer is looking for to create the quality your brand is looking to achieve.

When a consumer sets out to look for a quality product, they want to feel as though they have paid less than what the actual product is worth, the quality of the product far surpassing the amount they ended up paying. Fulfilling the need to exceed the consumer’s expectations, this is what true quality is all about.

If fulfilling the need to meet your consumer’s expectations is at the top of your company’s agenda, is it not essential for your brand’s products to meet a level of quality that does just that? Let me leave you pondering that for a bit.

In attempting to understand your customer’s definition of quality, it will be important to note that fulfilling consumer expectation and experience forms a part of that definition.

Let me give you an example; If a consumer orders a product that has met and passed all quality tests it needed to meet, that product for all intents and purposes is a quality item. But, if the order arrives later than promised or arrives with a missing screw or the incorrect color, the consumer may not define this product as an item of value and quality.

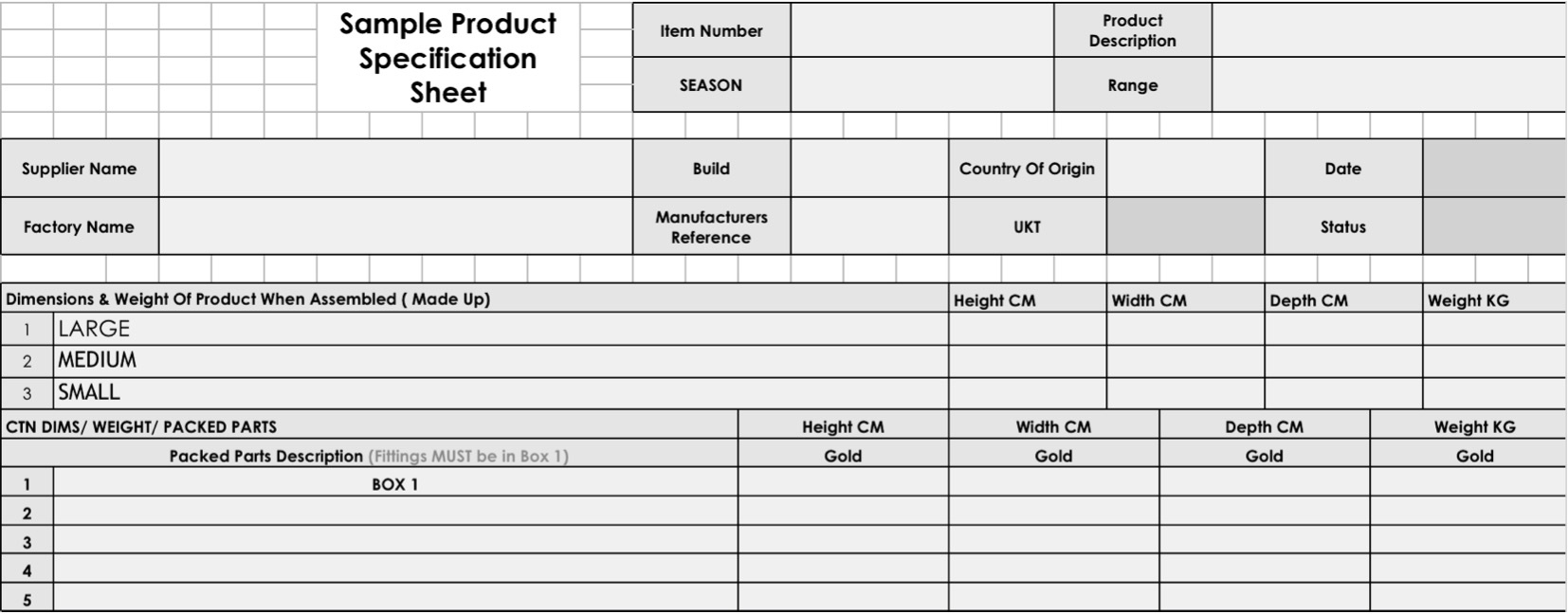

Striving for product quality is a stems right from the raw materials used, to the way in which it arrives to your customer, therefore every step needs to be taken into consideration.

The quality of a product can be defined in many ways and is almost always dependent on your specific consumer and their definition of quality for your specific item. So in that light, you will need to know exactly what your consumer is looking for to create the quality your brand is looking to achieve.

When a consumer sets out to look for a quality product, they want to feel as though they have paid less than what the actual product is worth, the quality of the product far surpassing the amount they ended up paying. Fulfilling the need to exceed the consumer’s expectations, this is what true quality is all about.

If fulfilling the need to meet your consumer’s expectations is at the top of your company’s agenda, is it not essential for your brand’s products to meet a level of quality that does just that? Let me leave you pondering that for a bit.

In attempting to understand your customer’s definition of quality, it will be important to note that fulfilling consumer expectation and experience forms a part of that definition.

Let me give you an example; If a consumer orders a product that has met and passed all quality tests it needed to meet, that product for all intents and purposes is a quality item. But, if the order arrives later than promised or arrives with a missing screw or the incorrect color, the consumer may not define this product as an item of value and quality.

Striving for product quality is a stems right from the raw materials used, to the way in which it arrives to your customer, therefore every step needs to be taken into consideration.

craze of fidget spinners and, where 200, 000 of these spinners have been recalled due to it

craze of fidget spinners and, where 200, 000 of these spinners have been recalled due to it  they want to know where its raw materials were sourced, how it was made, who made it and what its level of quality is. They ask themselves whether or not your product will be an investment in their lives.

The key here will be to know your target market, know your consumer. If you do not know what they want, you will struggle to be their go-to brand; you will lose out on their brand evangelism and praise affecting your bottom line

“Is this the type of brand and product you wish to create?”

Retailers today are under so much pressure with the current supply and demand of products, that quality and/or compliance is not always a priority.

“But, it should be!”

Bad quality and non-compliance both mean that your brand is at an unnecessarily high risk with regards to meeting regulations and your reputation. It will be worth all the hard yards that you put in from the creation and design to the manufacturing and distribution of your products. This will help mitigate unnecessary risk, saving you money and precious time.

they want to know where its raw materials were sourced, how it was made, who made it and what its level of quality is. They ask themselves whether or not your product will be an investment in their lives.

The key here will be to know your target market, know your consumer. If you do not know what they want, you will struggle to be their go-to brand; you will lose out on their brand evangelism and praise affecting your bottom line

“Is this the type of brand and product you wish to create?”

Retailers today are under so much pressure with the current supply and demand of products, that quality and/or compliance is not always a priority.

“But, it should be!”

Bad quality and non-compliance both mean that your brand is at an unnecessarily high risk with regards to meeting regulations and your reputation. It will be worth all the hard yards that you put in from the creation and design to the manufacturing and distribution of your products. This will help mitigate unnecessary risk, saving you money and precious time.

A POA is essential for filling out shippers exportation documents. This exportation document cannot be completed without a valid POA. Without it, your shipment will not be released, costing you time and money.

“So, what happens when one of these documents are not in order?”

You incur costs that begin adding up on a daily basis. Your shipment will be warehoused, where you will be billed for every day your shipment is there. It will be time consuming. Much of the paperwork mentioned above takes time to complete, but now you will be waiting on paperwork while raking up warehouse fees. This is not an ideal situation but can be avoided with thorough, well-kept, organized paperwork and a dash of patience to go along with it.

A POA is essential for filling out shippers exportation documents. This exportation document cannot be completed without a valid POA. Without it, your shipment will not be released, costing you time and money.

“So, what happens when one of these documents are not in order?”

You incur costs that begin adding up on a daily basis. Your shipment will be warehoused, where you will be billed for every day your shipment is there. It will be time consuming. Much of the paperwork mentioned above takes time to complete, but now you will be waiting on paperwork while raking up warehouse fees. This is not an ideal situation but can be avoided with thorough, well-kept, organized paperwork and a dash of patience to go along with it.

will provide an easier platform to discuss these matters in-depth, with absolute understanding and clarity. Personally I find Zoom a favorite for all conference calling, it has helped me stay in touch with a lot more ease than just relying on email.

Now that we have spoken about the means of communication, we need to address the frequency and manner of communication.

“How often do you phone your supplier to just talk about basic business operations?”

The more constant the flow of communication is, the more you will begin to get to know your supplier, and where your business sits in the grander scheme of their operations (and how much they stand to lose if they make mistakes).

This level of trust that you begin to build with your supplier will help to keep them honest and accountable if you happen to receive a delivery of products that are non compliant.

This kind of communication provides clarity and indicates to your supplier that you trust them to fix the problem to achieve the level of compliance that your company has set as the standard.

will provide an easier platform to discuss these matters in-depth, with absolute understanding and clarity. Personally I find Zoom a favorite for all conference calling, it has helped me stay in touch with a lot more ease than just relying on email.

Now that we have spoken about the means of communication, we need to address the frequency and manner of communication.

“How often do you phone your supplier to just talk about basic business operations?”

The more constant the flow of communication is, the more you will begin to get to know your supplier, and where your business sits in the grander scheme of their operations (and how much they stand to lose if they make mistakes).

This level of trust that you begin to build with your supplier will help to keep them honest and accountable if you happen to receive a delivery of products that are non compliant.

This kind of communication provides clarity and indicates to your supplier that you trust them to fix the problem to achieve the level of compliance that your company has set as the standard.

importers that do not pay on time so as to avoid those kinds of risks for themselves in the future.

What is advisable with regards to payment is ensuring that you have laid out all your payment terms with your supplier. In doing this you create a level of transparency with your supplier which can prove to be invaluable.

If you have been in this position before, as I am sure you have, I would say that the best practice here would be the same as tip #1;

Communication

You need to communicate your situation immediately, creating an honest and open relationship with your supplier which will put you in good stead for future orders.

importers that do not pay on time so as to avoid those kinds of risks for themselves in the future.

What is advisable with regards to payment is ensuring that you have laid out all your payment terms with your supplier. In doing this you create a level of transparency with your supplier which can prove to be invaluable.

If you have been in this position before, as I am sure you have, I would say that the best practice here would be the same as tip #1;

Communication

You need to communicate your situation immediately, creating an honest and open relationship with your supplier which will put you in good stead for future orders.

This knowledge creates an improvement in their service to you as operational times and

This knowledge creates an improvement in their service to you as operational times and

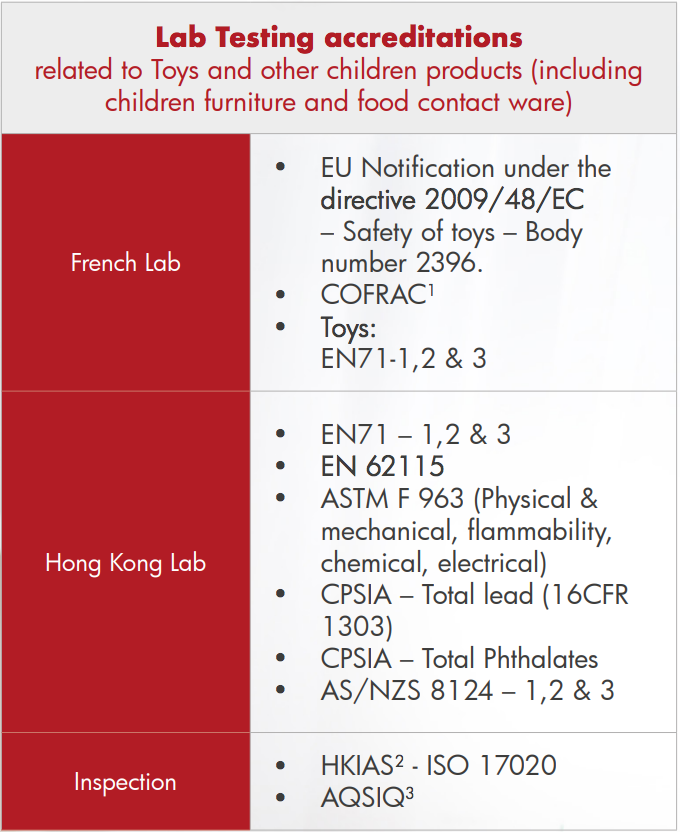

To minimise the possibility of heavy metal migration in toy manufacturing, the EU has tightened the regulations of toy quality control. Testing according to the revised EN71-3 standard includes 19 elements and the migration limits have been revised. The update has divided toys into three categories:

To minimise the possibility of heavy metal migration in toy manufacturing, the EU has tightened the regulations of toy quality control. Testing according to the revised EN71-3 standard includes 19 elements and the migration limits have been revised. The update has divided toys into three categories: