Corporate Social Responsibility (CSR) is a must for any toy brand that wants to achieve growth and avoid the costly implications of non compliance. A company that is testament to this fact is Lego. Last year the toy giant reported its highest revenue yet in its 85 year history, their profits rising 1.7% to 12.2bn kroner. This growth showcases the heights you can achieve through organizational commitment.

Global retail brands are increasingly wanting to partner with suppliers of children’s toys who can provide them with the appropriate environmental and social compliance.

Lego has been able to achieve their CSR goals through going above and beyond what any toy quality management system requires.

How have they done this?

Renewable energy.

In 2012 the toy company began investing in wind turbines to power their operations globally. As a result, in 2016 more than 360 gigawatt hours of energy was used by the LEGO Group to produce the more than 75 billion LEGO bricks sold around the world during the year.  They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

They initially had committed to making this transition by 2020, but they ended up meeting their target 3 years early! This is one great commitment to the realm of renewable energy.

Apart from this they are currently investing loads of money and time into finding alternatives to plastic for their famous building blocks.

As consumers increasingly dictate how manufacturers design and make toys, the power of adopting CSR and green initiatives as a part of your competitive strategy will have global results for your brand.

What do I mean by this?

The toy quality management system you choose to adopt will provide a framework for which CSR is able to be strategically implemented for your brand. Lego is a prime example of this. Whilst they are a children’s toy brand, they have committed fully to sourcing a more environmentally friendly plastic for their iconic plastic blocks. Even though they have not yet found a suitable alternative, their commitment and investment in trying to, puts them at the forefront of an initiative consumers the world over want to see and be a part of.

So I put the question to you…

How can your QMS leverage CSR for a globally competitive position?

Let’s take a bit of a deeper dive in… A QMS framework is just that: A framework that has been created to ensure quality in all areas from management to products, to customers, to factory processes and environmental impact. The ISO 14001:15 is the international standard used to navigate environmental impact and innovations. What are the key benefits of complying with ISO 14001:15?- It demonstrates compliance with current regulatory requirements.

- It increases leadership involvement and engagement of employees.

- Sie verbessert den Ruf des Unternehmens und das Vertrauen der Stakeholder durch strategische Kommunikation.

- It achieves strategic business aims by incorporating environmental issues into its business management.

- It provides a competitive and financial advantage through improved efficiencies and reduced costs.

- It encourages better environmental performance of suppliers by integrating them into the organization’s business systems.

How can your toy brand go about implementing ISO today?

We have outlined a stepped process which will help you prepare for compliance according to the environmental ISO 14001 framework for your brand;- You will need to identify all aspects and environmental impacts of your organization’s activities

- If you have not established an environmental policy for your organization, you will need to go ahead and do this.

- You will need to formalize your environmental procedures and publish them in company manuals and company policy.

- You will need to bring the company into compliance with all legal requirements and mandatory regulations.

- You will need to get the confirmation of compliance by all stakeholders such as clients and legal authorities.

- Lastly, you will need to obtain a certification of your environmental management system by a registered third party.

.png)

Dies ist der Punkt, an dem

Dies ist der Punkt, an dem Zu diesem Zeitpunkt wird eine Zufallsstichprobe von Möbeln ausgewählt, die dann einzeln daraufhin überprüft werden, ob sie die folgenden Kriterien erfüllen oder nicht;

Zu diesem Zeitpunkt wird eine Zufallsstichprobe von Möbeln ausgewählt, die dann einzeln daraufhin überprüft werden, ob sie die folgenden Kriterien erfüllen oder nicht;

A social compliance audit can be difficult to attain, but is an absolute necessity for that transparent supply chain your consumers today are demanding.

A social compliance audit ensures that a factory and its practices are abiding by all local laws and that you meet all of the social obligations as set out by the guidelines of the audit, from fair wages to no instances of child labor in a factory.

In this blog post, I will outline the exact procedure of this audit, the benefits it offers to your consumer electronics brand and how you can go about conducting this audit for yourself.

So, let’s dive in…

A social compliance audit can be difficult to attain, but is an absolute necessity for that transparent supply chain your consumers today are demanding.

A social compliance audit ensures that a factory and its practices are abiding by all local laws and that you meet all of the social obligations as set out by the guidelines of the audit, from fair wages to no instances of child labor in a factory.

In this blog post, I will outline the exact procedure of this audit, the benefits it offers to your consumer electronics brand and how you can go about conducting this audit for yourself.

So, let’s dive in…

Document reviews – Auditors will check all the documentation of the supplier to determine the presence of any possible child labour, an all too common violation within the consumer electronics industry. They also assess whether there are any violations of extended working hours and wages. They will also look into what types of social insurance are available to workers and review any fire and safety documentation, which will help to determine whether or not any safety precautions or plans are in place. They will also inspect whether or not there is any environmental monitoring being done and, if so, how it is conducted.

Employee interviews – The auditors conduct interviews with the factory in question staff, where they ask them about their working hours, overtime, and about their holiday/leave time. Auditors also like to cross check these statements by interviewing factory management to ensure there are no discrepancies. This helps to clarify whether there are any instances of abuse or misconduct between staff and management. In the case of a re-audit these interviews will then be conducted again to ensure improvement plans are being implemented properly.

Closing meeting with audit status – This meeting reveals the audit results of your CE factory and also makes suggestion for improvements. If you use

Document reviews – Auditors will check all the documentation of the supplier to determine the presence of any possible child labour, an all too common violation within the consumer electronics industry. They also assess whether there are any violations of extended working hours and wages. They will also look into what types of social insurance are available to workers and review any fire and safety documentation, which will help to determine whether or not any safety precautions or plans are in place. They will also inspect whether or not there is any environmental monitoring being done and, if so, how it is conducted.

Employee interviews – The auditors conduct interviews with the factory in question staff, where they ask them about their working hours, overtime, and about their holiday/leave time. Auditors also like to cross check these statements by interviewing factory management to ensure there are no discrepancies. This helps to clarify whether there are any instances of abuse or misconduct between staff and management. In the case of a re-audit these interviews will then be conducted again to ensure improvement plans are being implemented properly.

Closing meeting with audit status – This meeting reveals the audit results of your CE factory and also makes suggestion for improvements. If you use  In understanding the ethical compliance standards as laid out above, you are able to make informed decisions about the suppliers you choose to use in the manufacturing of your electrical products.

In understanding the ethical compliance standards as laid out above, you are able to make informed decisions about the suppliers you choose to use in the manufacturing of your electrical products.

On 23rd December 2014, the Consumer Product Safety Commission (CPSC) announced the recall of over 7 million coffee machines.Between 2010-2014, there were over 200 complaints of boiling water spraying out of the machine and approximately 90 burn injuries reported.It has been recently announced that Keurig has

On 23rd December 2014, the Consumer Product Safety Commission (CPSC) announced the recall of over 7 million coffee machines.Between 2010-2014, there were over 200 complaints of boiling water spraying out of the machine and approximately 90 burn injuries reported.It has been recently announced that Keurig has  In fact, the inventor today does not get a dime out of the sales of this popular children’s toy, as she was told her idea was not good enough and wouldn’t sell. Needless to say, millions of these toys are sold the world over.

But, she could count that as somewhat of a blessing…

Recently, over

In fact, the inventor today does not get a dime out of the sales of this popular children’s toy, as she was told her idea was not good enough and wouldn’t sell. Needless to say, millions of these toys are sold the world over.

But, she could count that as somewhat of a blessing…

Recently, over  Es stellt sich heraus, dass

Es stellt sich heraus, dass  Viele Unternehmen verfügen nicht über die umfangreichen geografischen Netze, die größere Einzelhändler haben.

Daher verbringen Ihre internen Mitarbeiter viel Zeit mit Reisen für Qualitätskontrollen und haben nicht genug Zeit, sich auf die Qualität eines Produkts zu konzentrieren. Dadurch verlangsamen sich oft die Produktionsprozesse, und die Zeit bis zur Markteinführung wird länger.

Nehmen wir das Beispiel des Fidget Spinners: Wie groß ist die Wahrscheinlichkeit, dass Ihr internes Team von der Nichtkonformität erfährt, bevor das Produkt auf den Markt kommt?

Denken Sie darüber nach.

Ein Vorfall wie der oben beschriebene setzt Ihre Marke einem unnötigen Risiko aus, das zu schlechter Publicity und erheblichen Umsatzeinbußen führen kann.

Dose Kann sich Ihre Organisation das leisten?

Viele Unternehmen verfügen nicht über die umfangreichen geografischen Netze, die größere Einzelhändler haben.

Daher verbringen Ihre internen Mitarbeiter viel Zeit mit Reisen für Qualitätskontrollen und haben nicht genug Zeit, sich auf die Qualität eines Produkts zu konzentrieren. Dadurch verlangsamen sich oft die Produktionsprozesse, und die Zeit bis zur Markteinführung wird länger.

Nehmen wir das Beispiel des Fidget Spinners: Wie groß ist die Wahrscheinlichkeit, dass Ihr internes Team von der Nichtkonformität erfährt, bevor das Produkt auf den Markt kommt?

Denken Sie darüber nach.

Ein Vorfall wie der oben beschriebene setzt Ihre Marke einem unnötigen Risiko aus, das zu schlechter Publicity und erheblichen Umsatzeinbußen führen kann.

Dose Kann sich Ihre Organisation das leisten?

Einige Prüfgeräte sind möglicherweise nur für ein bestimmtes Produkt geeignet, oder die Prüfverfahren werden aktualisiert, um den jüngsten Änderungen der Vorschriften Rechnung zu tragen.

Oft sind externe Anbieter in der Lage, technische Lösungen auf der Grundlage der oben genannten Spezifikationen anzubieten, zusammen mit Teams, die sich mit den neuen Prüfverfahren gut auskennen.

Externe Anbieter schicken ihre Inspektoren oft zu Schulungen, damit sie sich mit neuen Geräten und Prüfverfahren vertraut machen können, um sicherzustellen, dass eine qualitativ hochwertige Dienstleistung mit einer minimalen Rückrufquote angeboten wird.

Für externe Qualitätsdienstleister ist es von vorrangiger Bedeutung, über die neuesten Trends und Entwicklungen in Ihrer Branche auf dem Laufenden zu sein und die besten Verfahren zu kennen, die Sie befolgen sollten.

Diese Art von Wissen und Erfahrung kann zu Ihrem Wettbewerbsvorteil genutzt werden.

Einige Prüfgeräte sind möglicherweise nur für ein bestimmtes Produkt geeignet, oder die Prüfverfahren werden aktualisiert, um den jüngsten Änderungen der Vorschriften Rechnung zu tragen.

Oft sind externe Anbieter in der Lage, technische Lösungen auf der Grundlage der oben genannten Spezifikationen anzubieten, zusammen mit Teams, die sich mit den neuen Prüfverfahren gut auskennen.

Externe Anbieter schicken ihre Inspektoren oft zu Schulungen, damit sie sich mit neuen Geräten und Prüfverfahren vertraut machen können, um sicherzustellen, dass eine qualitativ hochwertige Dienstleistung mit einer minimalen Rückrufquote angeboten wird.

Für externe Qualitätsdienstleister ist es von vorrangiger Bedeutung, über die neuesten Trends und Entwicklungen in Ihrer Branche auf dem Laufenden zu sein und die besten Verfahren zu kennen, die Sie befolgen sollten.

Diese Art von Wissen und Erfahrung kann zu Ihrem Wettbewerbsvorteil genutzt werden.

Ihr Produkt.

Wenn Sie all dies zusammenzählen, werden Sie feststellen, dass die Gewinnspannen höher sind und dass Sie in der Lage sind, Angebot und Nachfrage Ihrer Produkte zu befriedigen, was Ihnen den gewünschten Wettbewerbsvorteil verschafft.

Werfen wir einen kurzen Blick auf die Lösung Technical Compliance File;

Dies ist eine Compliance-Lösung, die Ihnen einen zuverlässigen und genauen Einblick in Ihre Compliance-Prozesse ermöglicht.

Sie wird über eine webbasierte Plattform angeboten und ist eine

Ihr Produkt.

Wenn Sie all dies zusammenzählen, werden Sie feststellen, dass die Gewinnspannen höher sind und dass Sie in der Lage sind, Angebot und Nachfrage Ihrer Produkte zu befriedigen, was Ihnen den gewünschten Wettbewerbsvorteil verschafft.

Werfen wir einen kurzen Blick auf die Lösung Technical Compliance File;

Dies ist eine Compliance-Lösung, die Ihnen einen zuverlässigen und genauen Einblick in Ihre Compliance-Prozesse ermöglicht.

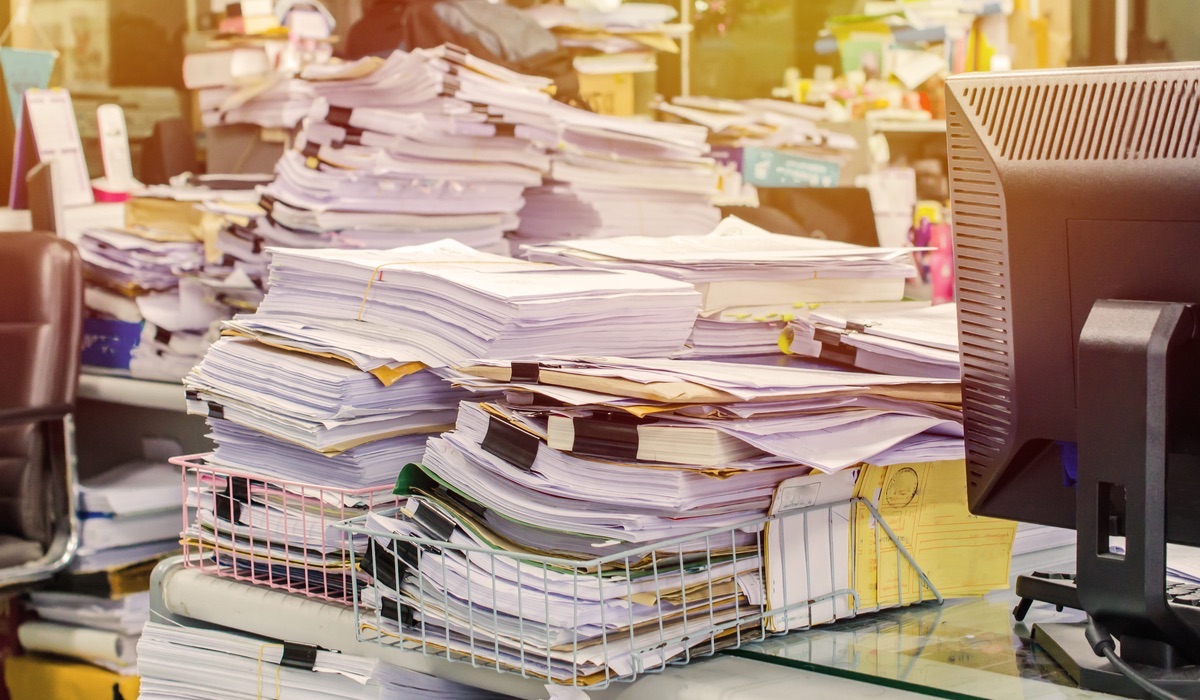

Sie wird über eine webbasierte Plattform angeboten und ist eine  Inspektionsberichte sind für die Freigabe von Sendungen durch den Zoll unerlässlich. Es ist Sache des Einzelhändlers und Ihres Qualitätsanbieters, eine Richtlinie für die Bewertung der Berichte aufzustellen.

Diese Richtlinie für die Berichtsbewertung bildet eine Grundlage für die Automatisierung, die den Umfang der manuellen Änderungen nach der Überprüfung der Berichte verringert. Die manuelle Überprüfung dieser Berichte verlangsamt die automatischen Versandprozesse immens und der gesamte Prozess wird weniger sinnvoll.

Ein externer Qualitätsanbieter ist in der Lage, Sie mit Branchenkenntnissen und bewährten Verfahren in Bezug auf Ratingberichte zu versorgen. Außerdem können Sie Ihre Rating-Berichte an die Anforderungen Ihres Produkts anpassen.

Sobald der Ratingbericht erstellt ist, kann Ihr Qualitätsdienstleister seine technischen Systeme nutzen, um tägliche Berichte sowohl an den Kunden als auch an das von Ihnen gewählte Frachtunternehmen zu senden. Dadurch wird der Freigabeprozess sowohl für Sie als auch für das Transportunternehmen wesentlich klarer und schneller.

Der Berg an Papierkram - von Einfuhrlizenzen bis hin zu vollständigen Inspektionsberichten - ist für sie kein Problem mehr, so dass sie einen rationalisierten, effizienten Prozess für Ihr Unternehmen ermöglichen.

Inspektionsberichte sind für die Freigabe von Sendungen durch den Zoll unerlässlich. Es ist Sache des Einzelhändlers und Ihres Qualitätsanbieters, eine Richtlinie für die Bewertung der Berichte aufzustellen.

Diese Richtlinie für die Berichtsbewertung bildet eine Grundlage für die Automatisierung, die den Umfang der manuellen Änderungen nach der Überprüfung der Berichte verringert. Die manuelle Überprüfung dieser Berichte verlangsamt die automatischen Versandprozesse immens und der gesamte Prozess wird weniger sinnvoll.

Ein externer Qualitätsanbieter ist in der Lage, Sie mit Branchenkenntnissen und bewährten Verfahren in Bezug auf Ratingberichte zu versorgen. Außerdem können Sie Ihre Rating-Berichte an die Anforderungen Ihres Produkts anpassen.

Sobald der Ratingbericht erstellt ist, kann Ihr Qualitätsdienstleister seine technischen Systeme nutzen, um tägliche Berichte sowohl an den Kunden als auch an das von Ihnen gewählte Frachtunternehmen zu senden. Dadurch wird der Freigabeprozess sowohl für Sie als auch für das Transportunternehmen wesentlich klarer und schneller.

Der Berg an Papierkram - von Einfuhrlizenzen bis hin zu vollständigen Inspektionsberichten - ist für sie kein Problem mehr, so dass sie einen rationalisierten, effizienten Prozess für Ihr Unternehmen ermöglichen.

Dies ist häufig darauf zurückzuführen, dass die internen Qualitätskontrollteams viel reisen müssen, was bedeutet, dass sie nicht genug Zeit haben, um die Genehmigungen zu erteilen, die für eine rechtzeitige Freigabe der Sendungen erforderlich sind.

Ich will mich nicht wiederholen, aber ein internes Team, das die mit dem Versand verbundene Logistik bewältigen kann, wäre zweifellos ein Traum, aber um sicher durch den Zoll zu kommen, muss man in all den anderen oben genannten Punkten effizient sein.

Interne Teams, die nicht über genügend Zeit, Ressourcen und technisches Fachwissen verfügen, werden es schwer haben, mit Problemen fertig zu werden, die andernfalls hätten vermieden werden können.

Also, so sieht es aus...

Das Qualitätsmanagement ist ein komplexes System, das 100% Ihrer Aufmerksamkeit und Konzentration erfordert.

Sind Sie in der Lage, diese Art von Zeit und Ressourcen zu investieren, um genau das zu gewährleisten?

Das ist eine Frage, die viele nicht beantworten wollen, aber die Realität ist, dass Sie sich die Zeit und die Ressourcen nicht leisten können, die nötig sind, um ein vollständig optimiertes Qualitätssystem zu schaffen, das qualitativ hochwertige Produkte für Ihre Marke pünktlich produziert.

Und was dann?

Es könnte sich lohnen, einen externen Qualitätsdienstleister zu beauftragen, der Ihnen die Zeit und die Ressourcen zur Verfügung stellt, die Sie für die Rationalisierung Ihrer Lieferkettenabläufe benötigen.

Ein externer Qualitätsdienstleister kann Ihnen Folgendes bieten;

* Die neuesten Produktvorschriften

* Technisches Fachwissen

* Er verfügt über die geeignete Technologie, um Ihre Abläufe zu optimieren

* Sie verfügen über das Know-how, wie Sie die internationale Logistik für Ihre Marke meistern können.

So können Sie sich auf das konzentrieren, worin Sie gut sind: die Herstellung hochwertiger Produkte und die Schaffung eines weltweit wettbewerbsfähigen Vertrauensverhältnisses zu Ihren Kunden.

Haben Sie Erfahrung in der Zusammenarbeit mit Qualitätskontrolldiensten von Dritten?

Dies ist häufig darauf zurückzuführen, dass die internen Qualitätskontrollteams viel reisen müssen, was bedeutet, dass sie nicht genug Zeit haben, um die Genehmigungen zu erteilen, die für eine rechtzeitige Freigabe der Sendungen erforderlich sind.

Ich will mich nicht wiederholen, aber ein internes Team, das die mit dem Versand verbundene Logistik bewältigen kann, wäre zweifellos ein Traum, aber um sicher durch den Zoll zu kommen, muss man in all den anderen oben genannten Punkten effizient sein.

Interne Teams, die nicht über genügend Zeit, Ressourcen und technisches Fachwissen verfügen, werden es schwer haben, mit Problemen fertig zu werden, die andernfalls hätten vermieden werden können.

Also, so sieht es aus...

Das Qualitätsmanagement ist ein komplexes System, das 100% Ihrer Aufmerksamkeit und Konzentration erfordert.

Sind Sie in der Lage, diese Art von Zeit und Ressourcen zu investieren, um genau das zu gewährleisten?

Das ist eine Frage, die viele nicht beantworten wollen, aber die Realität ist, dass Sie sich die Zeit und die Ressourcen nicht leisten können, die nötig sind, um ein vollständig optimiertes Qualitätssystem zu schaffen, das qualitativ hochwertige Produkte für Ihre Marke pünktlich produziert.

Und was dann?

Es könnte sich lohnen, einen externen Qualitätsdienstleister zu beauftragen, der Ihnen die Zeit und die Ressourcen zur Verfügung stellt, die Sie für die Rationalisierung Ihrer Lieferkettenabläufe benötigen.

Ein externer Qualitätsdienstleister kann Ihnen Folgendes bieten;

* Die neuesten Produktvorschriften

* Technisches Fachwissen

* Er verfügt über die geeignete Technologie, um Ihre Abläufe zu optimieren

* Sie verfügen über das Know-how, wie Sie die internationale Logistik für Ihre Marke meistern können.

So können Sie sich auf das konzentrieren, worin Sie gut sind: die Herstellung hochwertiger Produkte und die Schaffung eines weltweit wettbewerbsfähigen Vertrauensverhältnisses zu Ihren Kunden.

Haben Sie Erfahrung in der Zusammenarbeit mit Qualitätskontrolldiensten von Dritten?  Product specification can look anything like your products dimensions, the volume, it’s weight, the color and any specific labeling that it may need to meet regulation.

In your specifications you need to ensure that you are as specific as you can possibly be, from specific color palettes to the maximum weight of an electric blender. The more specific you are, the easier it will be for your supplier to meet your specifications.

These specifications will also provide your supplier’s quality control team with a standard/guide to monitor the production of the item appropriately.

This is where the

Product specification can look anything like your products dimensions, the volume, it’s weight, the color and any specific labeling that it may need to meet regulation.

In your specifications you need to ensure that you are as specific as you can possibly be, from specific color palettes to the maximum weight of an electric blender. The more specific you are, the easier it will be for your supplier to meet your specifications.

These specifications will also provide your supplier’s quality control team with a standard/guide to monitor the production of the item appropriately.

This is where the

A laptop’s battery overheating that when unattended whilst charging can cause fires would be classified as a critical defect.

A laptop’s battery overheating that when unattended whilst charging can cause fires would be classified as a critical defect.

Therefore an important question you should be asking your supplier before all this is, how they will go about preventing any quality issues that may arise during your operation?

Understanding how your supplier handles quality pressures and compliance procedures will help define what kind of relationship you have with them.

Before mass production, your supplier needs to provide you with a

Therefore an important question you should be asking your supplier before all this is, how they will go about preventing any quality issues that may arise during your operation?

Understanding how your supplier handles quality pressures and compliance procedures will help define what kind of relationship you have with them.

Before mass production, your supplier needs to provide you with a .jpg)

is also a dedicated IT team to ensuring the safety of the software and only API employees are allowed to make modifications to the platform.

is also a dedicated IT team to ensuring the safety of the software and only API employees are allowed to make modifications to the platform. Many of the compliance complexities that arise are in the collection and gathering of all the necessary documentation. Many manufacturers, importers and retailers today are still operating on outdated systems like spreadsheets, creating unreliable data and documentation, which creates an almost insurmountable task trying to maintain the information for each product reference.

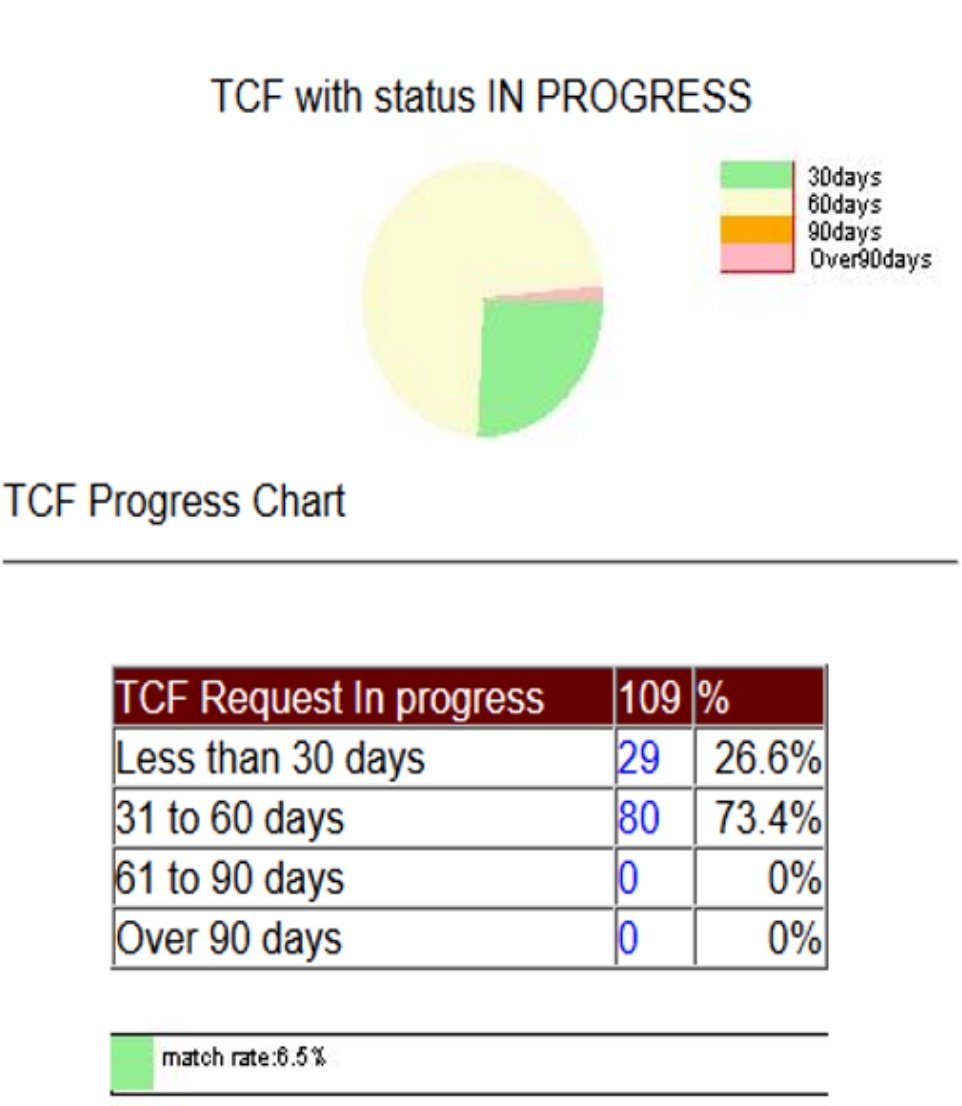

Many of the compliance complexities that arise are in the collection and gathering of all the necessary documentation. Many manufacturers, importers and retailers today are still operating on outdated systems like spreadsheets, creating unreliable data and documentation, which creates an almost insurmountable task trying to maintain the information for each product reference.  you insight into your compliance status whenever you need it. There are also progress charts allowing you actionable insight into timelines and your supplier progress. This solution is also able to store all your documents for up to 10 years, ensuring your documents are safely stored for any future reference.

you insight into your compliance status whenever you need it. There are also progress charts allowing you actionable insight into timelines and your supplier progress. This solution is also able to store all your documents for up to 10 years, ensuring your documents are safely stored for any future reference.